Introduction:

Aluminum veneer and aluminum-plastic composite panels are integral components in modern construction, offering durability, versatility, and aesthetic appeal. However, understanding the differences between aluminum plates and aluminum substrates is crucial for selecting the most suitable option for your specific needs. In this article, we delve into the key distinctions between these two materials to help you make informed decisions for your projects.

Difference 1: Materials Used:

Aluminum plates consist of pure metal, while aluminum-plastic panels combine metal with polyethylene plastic. This fundamental difference in composition influences various aspects of their performance and applications.

Difference 2: Types:

Comparatively, aluminum plates are heavier than aluminum-plastic panels of the same specifications. Factors such as material density and structural design contribute to this weight disparity.

Difference 3: Price:

The price of aluminum plates is generally higher than that of aluminum-plastic panels. Various factors, including the type of aluminum, coating materials, and processing techniques, affect the overall cost of each material.

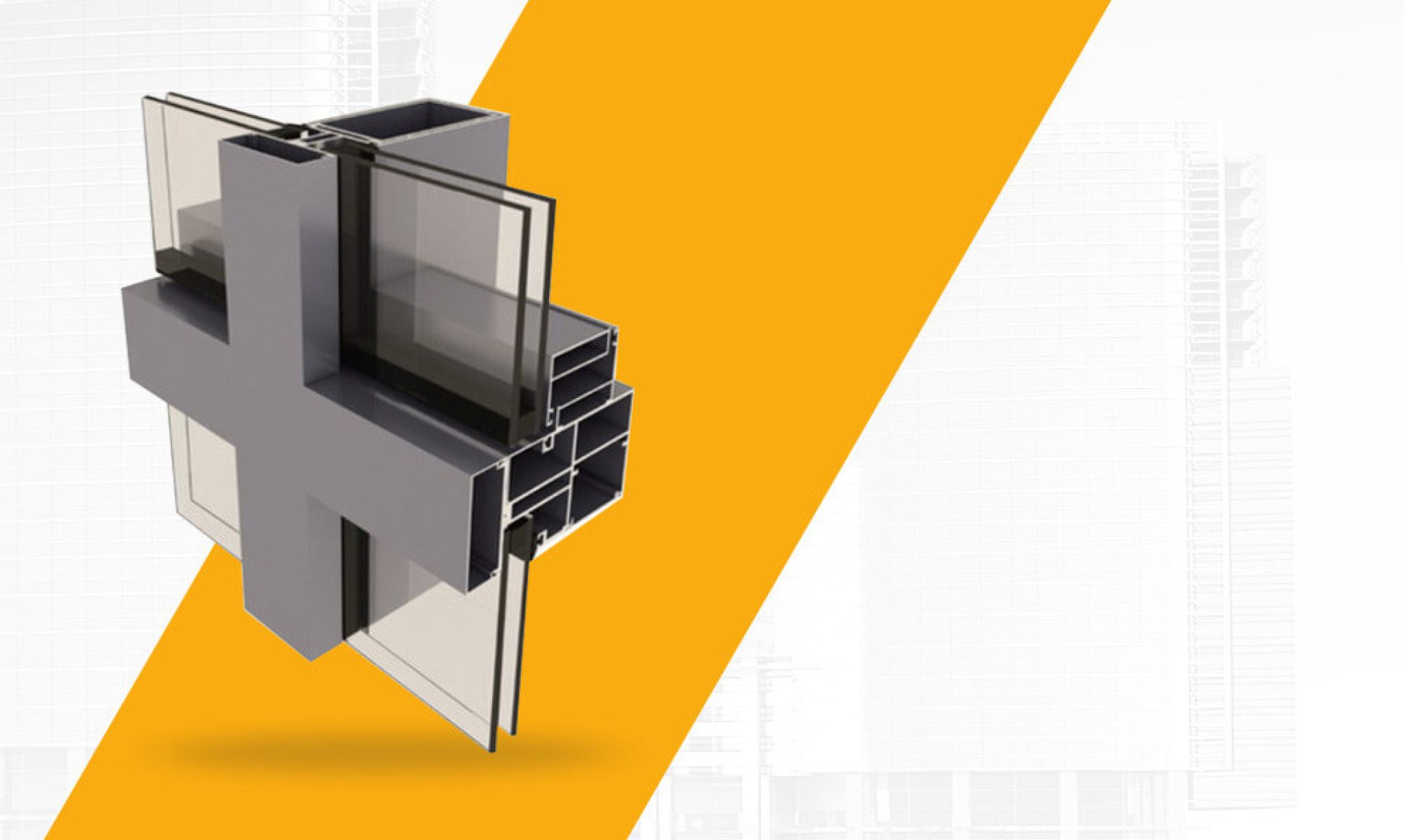

Difference 4: Installation Methods:

Aluminum panels are processed and shaped before arriving at the construction site, whereas aluminum-plastic panels undergo processing and forming on-site. This distinction in installation methods impacts project timelines and logistical considerations.

Difference 5: Keel Structure:

The choice of keel structure differs between aluminum panels and aluminum-plastic panels, with the former utilizing light steel keel structures and the latter employing wooden keel structures. This variation in mounting systems affects structural integrity and installation requirements.

Conclusion:

In conclusion, the differences between aluminum plates and aluminum-plastic panels extend beyond surface-level distinctions, encompassing material composition, weight, price, installation methods, and structural considerations. By understanding these nuances, you can effectively leverage the unique properties of each material to optimize the outcomes of your construction projects.