Introduction

In the realm of LED lighting, the choice of materials for lamp shells plays a crucial role in performance and durability. While stainless steel has been a traditional option, aluminum emerges as a superior alternative. In this article, we delve into the advantages of aluminum for LED lamp shells, shedding light on its benefits over stainless steel.

Advantages of Aluminum for LED Lamp Shells

Aluminum boasts several advantages over stainless steel, making it an ideal choice for LED lamp shells. Its exceptional heat dissipation properties, ease of processing, resistance to oxidation, and cost-effectiveness make it a preferred material for high-power LED lamps, ensuring optimal performance and longevity.

Importance of Heat Dissipation in LED Lighting

Effective heat dissipation is crucial for LED lamp performance, influencing both lifespan and efficiency. Aluminum’s superior thermal conductivity enables efficient heat transfer, preventing overheating and ensuring consistent light output over time, thus enhancing the overall performance and reliability of LED lamps.

Applications of Aluminum in LED Lamp Manufacturing

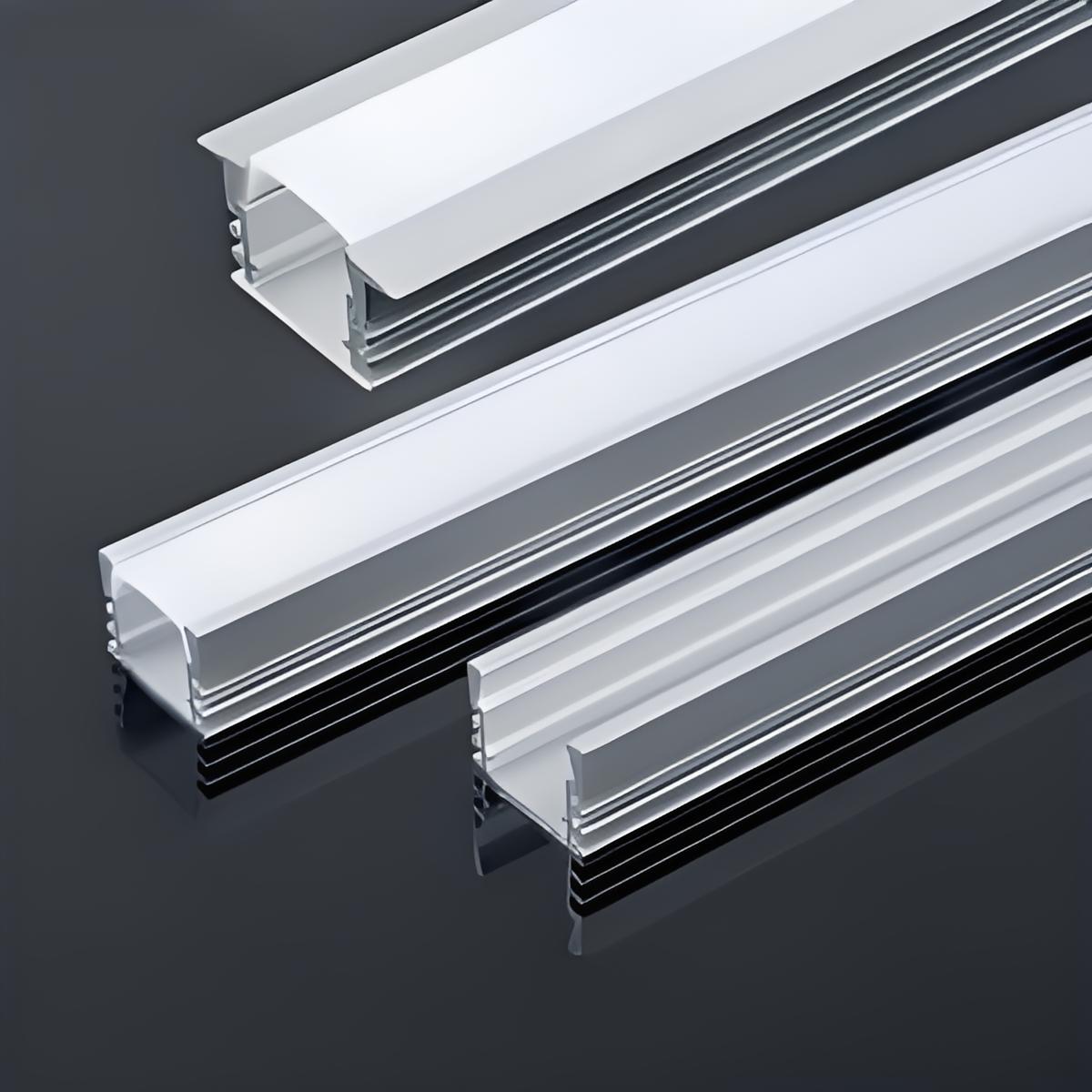

Across various manufacturing processes, aluminum shines as a versatile material for LED lamp shells. From die-cast to turned and stretched aluminum profiles, manufacturers leverage aluminum’s properties to create durable and efficient LED lighting solutions for a wide range of applications, from commercial to residential settings.

Conclusion

As the demand for efficient and sustainable lighting solutions grows, aluminum emerges as a standout choice for LED lamp shells. Its unparalleled heat dissipation capabilities, ease of processing, and cost-effectiveness position it as a frontrunner in the LED lighting industry, offering illuminating possibilities for a brighter and more energy-efficient future.