Introduction

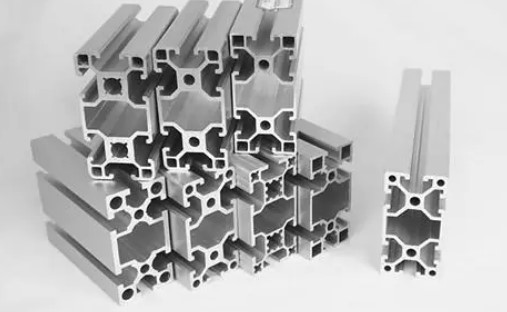

Industrial aluminum profiles are integral components in various industries, offering strength, versatility, and sustainability. Understanding the meticulous production process behind these profiles sheds light on their importance and application in modern manufacturing.

Prototype Design

The journey of industrial aluminum profile production begins with meticulous prototype design. This crucial phase involves determining material specifications, dimensions, and structural integrity based on customer requirements and usage environments. Feasibility analysis ensures that the design aligns with manufacturing capabilities and product standards.

Material Selection

The selection of aluminum alloys plays a pivotal role in determining the properties and performance of industrial aluminum profiles. Common alloys like 6063, 6061, and 6082 are chosen based on factors such as mechanical properties, corrosion resistance, and maintenance requirements, ensuring product stability and uniformity.

Billet Processing

Billet processing encompasses forging, extrusion, and casting methods, with extrusion being predominant. Through controlled pressure extrusion, aluminum strips are shaped into desired profiles, with variables like temperature and pressure meticulously regulated to prevent defects and ensure product integrity.

Surface Treatment and Processing

Surface treatment methods like spraying, anodizing, and thermal transfer enhance the appearance and functionality of aluminum profiles. These processes not only beautify the surface but also improve corrosion resistance, enhancing product durability and market competitiveness.

Assembly and Packaging

The final stages involve assembly and packaging, where attention to detail ensures the integrity of the finished product. Proper assembly techniques and secure packaging protect aluminum profiles during transit and storage, maintaining their quality until they reach the end-user.

Conclusion

The art of industrial aluminum profile production lies in the meticulous execution of each step in the manufacturing process. From prototype design to assembly, every detail influences the quality and performance of aluminum profiles crucial in construction, transportation, and machinery manufacturing. By understanding these processes, manufacturers can ensure the production of high-quality, efficient, and sustainable aluminum profiles to meet the demands of various industries.