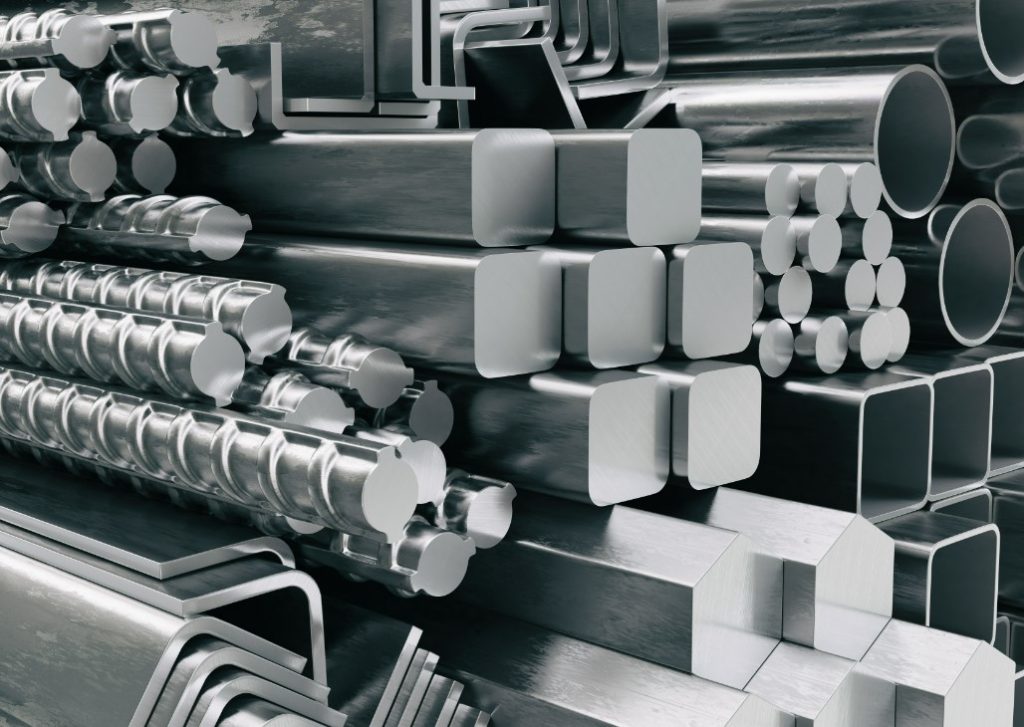

Introduction to Aluminum Alloy Pipes in Marine Engineering

Marine engineering stands as a testament to human ingenuity, pushing the boundaries of exploration and resource extraction. Yet, beneath the waves lies an unforgiving environment characterized by high temperatures, humidity, and salinity, posing formidable challenges to infrastructure durability. Enter aluminum alloy pipes, the unsung heroes of marine engineering, seamlessly blending corrosion resistance, lightweight design, and high strength to navigate the complexities of underwater operations.

Application of Aluminum Alloy Pipes in Marine Engineering

Submarine Oil and Gas Pipelines: In the realm of offshore oil extraction and transportation, the reliability of pipelines is paramount. Aluminum alloy pipes emerge as the preferred choice, boasting exceptional corrosion resistance and mechanical prowess. Their deployment in laying submarine pipelines ensures prolonged operation amidst the corrosive forces of seawater, minimizing maintenance disruptions and enhancing overall efficiency.

Structural Support and Equipment Connection in Offshore Platforms: Beyond the depths, aluminum alloy pipes serve as the backbone of offshore platforms, providing structural integrity and equipment connectivity. From stabilizing towering structures to facilitating fluid transfer, these pipes exemplify versatility and reliability in the face of turbulent marine environments.

Analysis of Corrosion Resistance of Aluminum Alloy Pipes

Formation of Oxide Film: At the heart of aluminum alloy’s corrosion resistance lies the formation of a dense oxide film. This natural barrier shields the metal from external corrosive agents, fortifying its longevity and performance in marine settings.

Resistance to Seawater Erosion: Seawater, notorious for its corrosive nature, poses a formidable threat to underwater infrastructure. Aluminum alloy pipes, however, stand resilient against such onslaughts, steadfastly resisting the erosive forces of seawater and ensuring sustained operational efficiency.

Stress Corrosion Cracking Resistance: In the tumultuous depths, pipelines are subjected to various stresses, heightening the risk of corrosion-induced failures. Yet, aluminum alloy pipes defy such odds, exhibiting exceptional resistance to stress corrosion cracking and safeguarding against catastrophic ruptures.

Surface Treatment Measures: To further augment their corrosion resistance, aluminum alloy pipes undergo meticulous surface treatments. Techniques such as anodizing and anti-corrosion coatings serve as additional layers of protection, bolstering the pipes’ durability and longevity in marine environments.

Conclusion

In the ever-evolving landscape of marine engineering, aluminum alloy pipes stand as beacons of innovation and reliability. Their unmatched corrosion resistance, coupled with lightweight design and robust mechanical properties, heralds a new era of sustainable infrastructure development beneath the waves. As we continue to explore the depths of our oceans, let us embrace the transformative potential of aluminum alloys, shaping a future where marine engineering thrives amidst adversity.