Introduction to Aluminum Heatsinks

What are Aluminum Heatsinks?

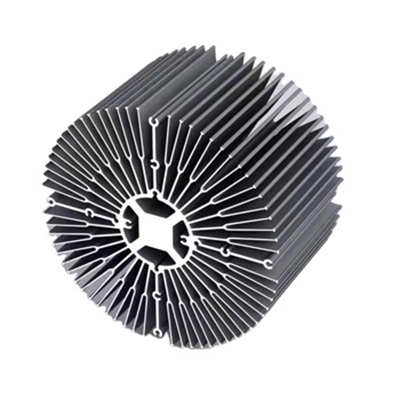

An aluminum heatsink is a crucial component in modern electronic devices, functioning to dissipate heat generated during operation. Constructed primarily from aluminum, a metal known for its excellent thermal conductivity and lightweight properties, these heatsinks are designed to maintain optimal temperatures within electronic systems. Aluminum heatsinks come in various shapes and sizes, tailored to specific applications, from small chips in a smartphone to large components in industrial machinery. The use of aluminum not only ensures efficient heat dispersion but also contributes to the durability and longevity of the device, protecting sensitive components from overheating and potential damage.

The Importance of Heatsinks in Electronics

Heatsinks, particularly those made from aluminum, play a vital role in electronic and computing devices. As electronic components such as processors and power units operate, they generate significant amounts of heat. If this heat is not effectively removed, it can lead to reduced efficiency, system instability, or even permanent damage. Aluminum heatsinks provide a practical solution by absorbing and dissipating this heat into the surrounding environment. This process helps maintain an optimal operating temperature, ensuring the reliable and efficient performance of the device. The significance of aluminum heatsinks extends beyond just cooling; they are pivotal in enabling modern electronics to achieve higher speeds and greater power densities without compromising on reliability and lifespan.

Overview of Aluminum as a Material for Heatsinks

Aluminum is a preferred material for manufacturing heatsinks due to its excellent thermal conductivity, which is crucial for effective heat dissipation. Its physical properties, such as low density and high malleability, also make aluminum an ideal choice. This allows for the creation of intricate heatsink designs that can maximize surface area and enhance heat transfer efficiency. Aluminum is also corrosion-resistant and offers a good balance between cost and performance, making it a popular choice in a wide range of applications. Furthermore, aluminum heatsinks are lightweight, which is especially beneficial in portable electronics where every gram counts. The material’s recyclability adds an environmental benefit, aligning with the growing demand for sustainable manufacturing practices.

The Science Behind Aluminum Heatsinks

Conductivity and Heat Dissipation

The effectiveness of aluminum heatsinks lies in the inherent properties of aluminum, particularly its thermal conductivity. This physical trait refers to the ability of a material to conduct heat, which in the case of aluminum, is significantly higher than many other metals used in heatsink production. The high thermal conductivity of aluminum allows for rapid heat absorption from the source, such as a CPU or GPU, and efficient dispersion into the surrounding air. This heat transfer is further facilitated by the design of the heatsink, which often includes fins or pins that increase the surface area, allowing more heat to be dissipated over a larger area. As a result, aluminum heatsinks are a cornerstone in thermal management systems, balancing efficiency and cost-effectiveness.

Aluminum Alloys Used in Heatsinks

While pure aluminum has favorable properties for heat dissipation, aluminum alloys are often used in heatsink manufacturing to enhance performance and durability. These alloys, which typically include elements like copper, silicon, magnesium, and zinc, are engineered to improve specific properties such as strength, corrosion resistance, and thermal conductivity. For instance, the addition of copper can significantly increase the alloy’s thermal conductivity, making it more efficient in heat transfer. The choice of alloy depends on the application’s specific requirements, balancing factors like thermal performance, weight, and cost. The versatility of aluminum alloys makes them adaptable to a wide range of heatsink applications, from consumer electronics to high-power industrial systems.

Comparing Aluminum with Other Heatsink Materials

In the realm of heatsink materials, aluminum often competes with materials like copper and composite materials. Each material has its advantages and trade-offs. Copper, for instance, has a higher thermal conductivity than aluminum but is also heavier and more expensive. This makes copper ideal for applications where maximum heat dissipation is needed, but the weight and cost are less of a concern. Composite materials, on the other hand, can be engineered to offer unique properties but may not provide the same level of thermal performance as metal heatsinks. Aluminum strikes a balance between performance, weight, and cost, making it a widely applicable choice for a broad range of thermal management applications. Its versatility and balance of properties explain why aluminum heatsinks are so prevalent in electronics and computing devices.

FAQ Generation

Frequently Asked Questions about Aluminum Heatsinks

Q1: What are the advantages of using aluminum for heatsinks?

A1: Aluminum is preferred for heatsinks due to its high thermal conductivity, lightweight, cost-effectiveness, and corrosion resistance. These properties make it ideal for efficient heat dissipation in various electronic applications.

Q2: How does an aluminum heatsink work?

A2: An aluminum heatsink works by absorbing heat from a heat-generating electronic component and dissipating it into the surrounding air. This process is enhanced by the heatsink’s design, which maximizes surface area for better heat transfer.

Q3: Can aluminum heatsinks be used in high-power applications?

A3: Yes, aluminum heatsinks are suitable for high-power applications. They are often designed with specific alloys and shapes to handle increased thermal loads effectively.

Q4: What factors should be considered when choosing an aluminum heatsink?

A4: When choosing an aluminum heatsink, consider the thermal requirements, size constraints, weight considerations, and the specific application’s environmental conditions.

Q5: How does the design of an aluminum heatsink affect its performance?

A5: The design, including the shape, size, and surface area of the fins or pins, significantly impacts the heatsink’s performance. A well-designed heatsink maximizes heat dissipation efficiency while fitting into the spatial constraints of the device.