Introduction

Aluminum profiles, often hidden heroes in various industries, possess a remarkable set of characteristics that contribute to their widespread applications. Understanding these traits is crucial for anyone interested in the versatile world of aluminum. In this article, we delve into the unique characteristics that make aluminum profiles stand out and explore their significance in diverse applications.

Corrosion Resistance

One of aluminum’s standout features is its exceptional corrosion resistance. With a density only about one-third that of steel, copper, or brass, aluminum showcases remarkable endurance in various environments, including air, water, and chemical systems. Real-world scenarios underscore the reliability of aluminum in the face of corrosion challenges.

Conductivity

Aluminum’s excellent electrical conductivity is a driving force behind its selection in various applications. Compared to copper, aluminum boasts nearly half the electrical conductivity on an equal weight basis. We explore practical applications where aluminum’s conductivity plays a pivotal role, making it a preferred choice in specific industries.

Thermal Conductivity

The thermal conductivity of aluminum alloy, approximately 50-60% that of copper, positions aluminum as a key player in manufacturing heat-related products. From heat exchangers to automobile components, aluminum’s thermal properties prove beneficial in diverse applications, enhancing efficiency and performance.

Non-Ferromagnetic Properties

The fact that aluminum is non-ferromagnetic holds significant importance, especially in the electronics and electrical industries. Additionally, its non-spontaneous ignition feature adds a layer of safety, making it a suitable choice in scenarios involving flammable materials. We explore how these properties impact specific industries.

Processability

The machinability of aluminum profiles is unparalleled. However, it requires specialized tools and processing equipment due to the varying characteristics across deformed and cast aluminum alloys. We uncover the intricacies of working with aluminum and the importance of employing the right tools for optimal results.

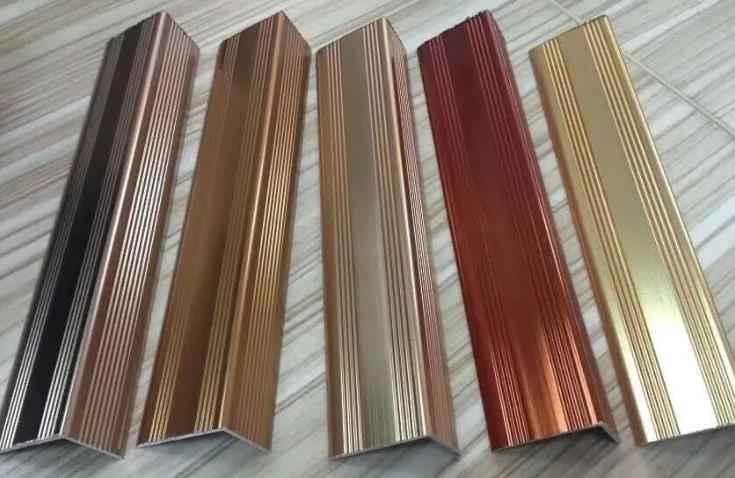

Formability

Aluminum alloy forming, encompassing extrusion, stamping, and die casting, showcases the material’s adaptability. We discuss the governing factors and delve into specific applications where aluminum’s formability shines. From intricate designs to large-scale components, aluminum profiles offer versatility in shaping.

Recyclability

As sustainability takes center stage, aluminum emerges as an eco-friendly material with extremely high recyclability. We shed light on the recycling process, transforming aluminum into secondary aluminum that mirrors the properties of primary aluminum. The environmental benefits of using recycled aluminum are highlighted.

Conclusion

In conclusion, the characteristics of aluminum profiles set them apart as a versatile and sustainable material. From corrosion resistance to exceptional conductivity and recyclability, aluminum continues to shape industries worldwide. This exploration merely scratches the surface, encouraging further investigation into the world of aluminum and its endless possibilities. Join us on this journey of unlocking the secrets of aluminum profiles and their diverse applications.