Introduction

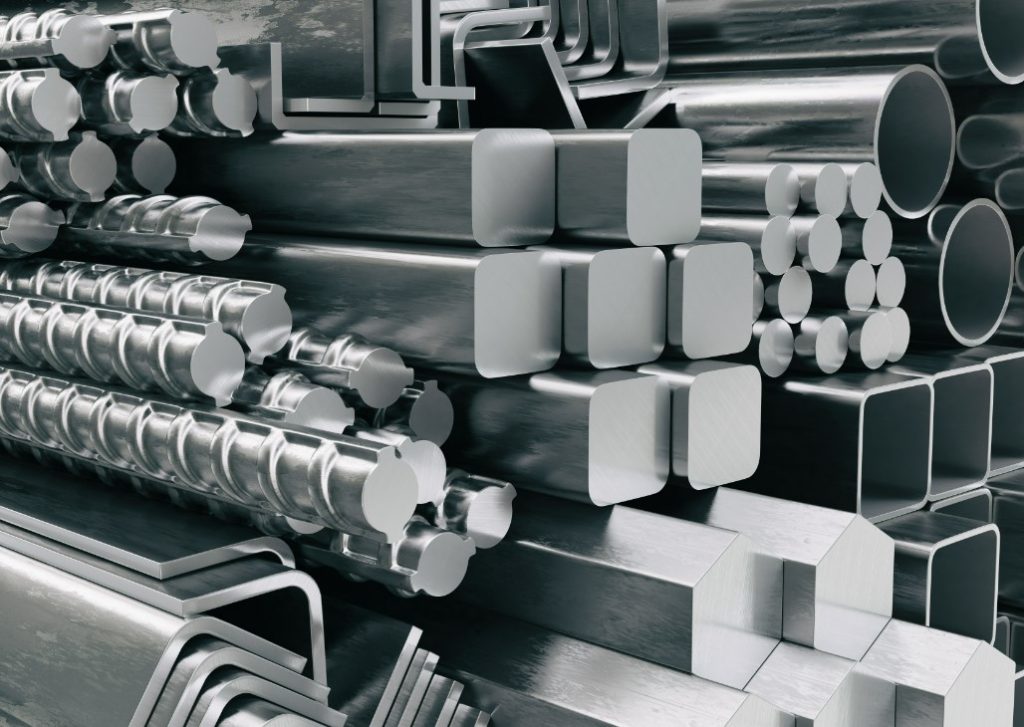

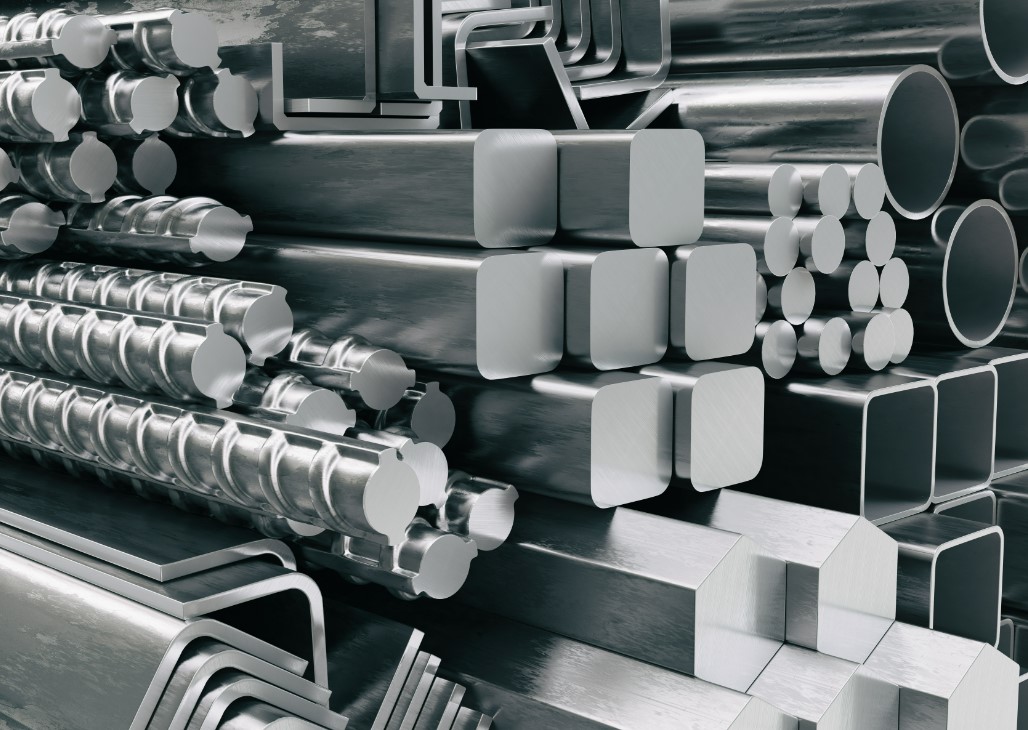

In the metal industry, aluminum has long been cherished for its lightweight and durability. As our global community grows increasingly eco-conscious, the demand for environmentally friendly manufacturing processes has never been higher. This is particularly evident in the realm of metal surface treatments, where aluminum oxidation is emerging as a preferable alternative to traditional electroplating. But what exactly is driving this change?

Environmental and Health Impacts of Aluminum Electroplating

Aluminum electroplating, once the standard for metal finishing, is now under scrutiny for its environmental and health ramifications. The process generates an overwhelming volume of complex wastewater, brimming with hazardous chemicals and heavy metals. These substances, challenging to treat and potentially devastating to natural water sources, pose a grave ecological threat. Additionally, the process emits a cocktail of noxious gases — including various acid and alkali mists — that harm not only our environment but also the health of those working with them. The waste residue, laden with heavy metals, further exacerbates the environmental hazard, cementing electroplating’s reputation as an unsustainable practice.

Benefits of Aluminum Oxidation

Aluminum oxidation, however, paints a greener picture. This advanced process significantly curtails the environmental footprint, producing fewer pollutants while maintaining the metal’s esteemed qualities. With superior efficiency and lower pollution levels than its electroplating counterpart, aluminum oxidation is swiftly gaining traction. It’s a testament to how technological innovations can foster more sustainable industrial practices without sacrificing performance.

The Shift to Aluminum Oxidation

The shift towards aluminum oxidation is a reflection of the changing tides in industry standards. Across the board, companies are adopting greener methods to comply with environmental regulations and public expectations. Real-world cases from the automotive to the aeronautical industries showcase a successful transition to oxidation techniques. This paradigm shift is not just a trend but a robust movement towards a more sustainable future in metal processing.

Conclusion

The decision to pivot from aluminum electroplating to oxidation is more than a mere change in manufacturing processes; it is a commitment to environmental stewardship and human health. As we continue to witness advancements in aluminum treatment technologies, the emphasis on sustainability is poised to grow even stronger. By embracing these eco-friendly practices, the aluminum industry sets a standard for responsible production, ensuring a healthier planet for generations to come.