Introduction

The world of aluminum can be a labyrinth of terminology, especially for industry newcomers. One common area of confusion lies between “aluminum alloy profiles” and “aluminum profiles.” Let’s demystify these terms and understand their essence.

The Fundamental Differences

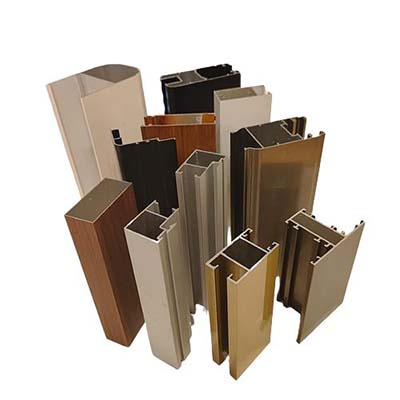

Aluminum profiles, often referred to as aluminum alloy profiles, are distinctly different from aluminum alloys. Picture this: while aluminum alloy is the raw material, aluminum profiles are the crafted end products, ready for direct application. It’s akin to comparing raw clay to a sculpted vase—the essence is the same, but the form and function differ.

Understanding Aluminum Profile Formation

Creating an aluminum profile isn’t a one-step game. It involves a triad of essential processes:

- Casting

- Extrusion

- Surface treatment

These procedures transform the raw aluminum into profiles of varied cross-sectional shapes.

A Glimpse into Aluminum Ingots and Rods

Laying the groundwork for all aluminum profiles are the ingots and rods. Typically ranging from 8-12 meters in length, they come in diameters of D90mm, D105mm, D120mm, and D178mm. Notably, the 6063 material dominates the Chinese market, underscoring its quality and applicability.

Unfolding the Processes

- Melting and Casting: This foundational process involves batching, smelting, and casting, marking the genesis of aluminum production.

- Extrusion: Think of it as giving shape to the aluminum. A mold, defined by a cross-sectional design, paves the way. The heated, round cast rod then gets its new form via an extruder.

- Surface Treatment: This is where the aluminum profile gets its final look. Anodized aluminum is a favorite, granting visual effects ranging from a sandy surface to bright white or even oxidized colors.

Applications in Our World

Aluminum profiles touch our lives in more ways than we realize. On one end, we have architectural profiles shaping our buildings, evident in doors, windows, and curtain walls. On the other, industrial profiles are the unsung heroes of production lines, machinery, protective shields, and more. The electronic machinery industry and clean rooms particularly benefit from these profiles.

Conclusion

While the differences between aluminum alloys and profiles might seem subtle, they’re pivotal in the industry. Armed with this knowledge, both industry veterans and newcomers can navigate the aluminum landscape more proficiently.