Introduction

Industrial aluminum profiles play a crucial role in various sectors, yet they often face the challenge of surface yellowing. This article delves into the causes of this common issue, offering insights into maintaining the desired quality and appearance of these profiles.

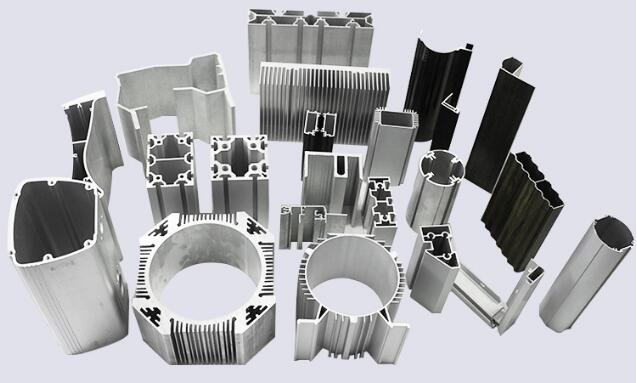

Overview of Industrial Aluminum Profiles

Industrial aluminum profiles are known for their durability and versatility. Typically, these profiles exhibit a silvery-white surface, which is sometimes marred by defects like yellowing. Understanding the root causes of this issue is key to maintaining their aesthetic and functional integrity.

Causes of Surface Yellowing

Surface yellowing in aluminum profiles can generally be traced back to two primary sources: the extrusion process and the subsequent surface treatment. Each of these stages holds potential pitfalls that can lead to discoloration.

Cooling Process and Its Impact

After extrusion, profiles undergo a cooling process to enhance their mechanical properties. The type of coolant used here plays a pivotal role. Water or oil-based coolants can react with aluminum, especially if copper content is high, leading to surface yellowing due to aluminum’s reactive nature.

Importance of Surface Oxide Film

The oxide film on aluminum profiles not only boosts corrosion resistance but also adds to their aesthetic appeal. Prior to surface treatment, thorough cleaning of the extruded profiles is essential. Any residual oil stains can hinder the oxidation process, causing uneven coloring and yellowing.

Challenges in Surface Treatment

The oxidation process is crucial for even coloring, but improper cleaning can result in inadequate oxide film development. This inconsistency is a major contributor to surface yellowing.

Preventative Measures and Best Practices

To prevent yellowing, it’s important to adhere to best practices in cooling and cleaning. Proper selection of coolants and meticulous cleaning can ensure a uniform and stable oxide film, preserving the desired appearance of the aluminum profiles.

Conclusion

Understanding the causes of surface yellowing in industrial aluminum profiles is vital for manufacturers aiming for high-quality outputs. By focusing on proper extrusion processes and surface treatments, the industry can effectively tackle this challenge, ensuring the production of pristine, high-standard aluminum profiles.