Introduction

In the ever-evolving landscape of automobile manufacturing, the use of aluminum alloy has emerged as a game-changer. Its lightweight properties coupled with exceptional strength make it an indispensable material in crafting efficient and high-performance vehicles. This article delves into the diverse applications of aluminum alloy in key automobile parts, shedding light on its significance in shaping the future of automotive engineering.

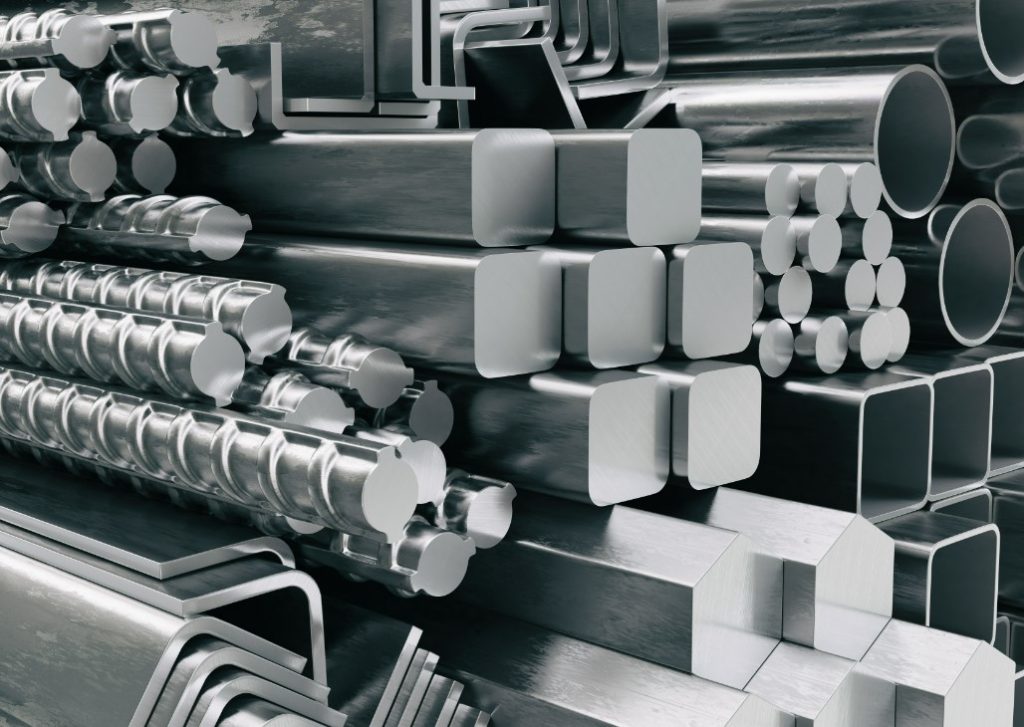

Application of Aluminum Alloy in Main Automobile Parts

Aluminum Cylinder Block and Cylinder Head: Aluminum’s excellent thermal conductivity and corrosion resistance make it an ideal choice for engine components, leading to the widespread use of all-aluminum cylinder blocks and heads in automobile manufacturing.

Aluminum Radiator: Aluminum radiators prioritize durability and heat dissipation capabilities, enhancing the performance and reliability of automotive cooling systems.

Aluminum Alloy Wheels: With approximately 50% usage rate, aluminum alloy wheels are essential safety components, offering high strength, lightweight construction, and superior heat dissipation properties. Advancements in design and manufacturing have led to thinner, lighter, and safer aluminum wheels.

Aluminum Bumper: Aluminum bumpers, known for their high safety factor and durability, contribute to vehicle safety while minimizing overall weight.

Aluminum Body: Recognized as the most crucial component of a car, lightweight aluminum bodies significantly reduce vehicle mass, improving fuel efficiency and performance.

Chassis Components: Aluminum’s potential for weight reduction is maximized in chassis systems, where it replaces steel, enhancing vehicle dynamics and handling.

Advantages of Aluminum Alloy in Automobile Parts

Lightweight construction improves fuel efficiency and performance.

High strength and durability ensure safety and longevity.

Superior thermal conductivity enhances heat dissipation capabilities.

Corrosion resistance increases component lifespan.

Environmental benefits through reduced vehicle weight and recyclability.

Future Trends and Innovations

As automotive manufacturers continue to prioritize lightweight design and sustainability, ongoing research and development efforts focus on advancing aluminum alloy technologies. Innovations such as all-aluminum bodies and further optimization of component design aim to push the boundaries of automotive performance and efficiency.

Conclusion

In conclusion, the application of aluminum alloy in main automobile parts represents a cornerstone of innovation in the automotive industry. From enhancing safety and performance to promoting sustainability, aluminum’s versatility continues to drive progress in modern vehicle design. As technology evolves and consumer demands shift, aluminum alloy remains poised to play a central role in shaping the future of automobiles.