Introduction

In the dynamic landscape of automotive manufacturing, aluminum profiles emerge as a game-changer, offering versatility, strength, and sustainability. This article delves into the pivotal role played by aluminum profiles in reshaping the automotive industry, driving innovation, and meeting the demands of a rapidly evolving market.

Applications of Aluminum Profiles in Automobile Manufacturing

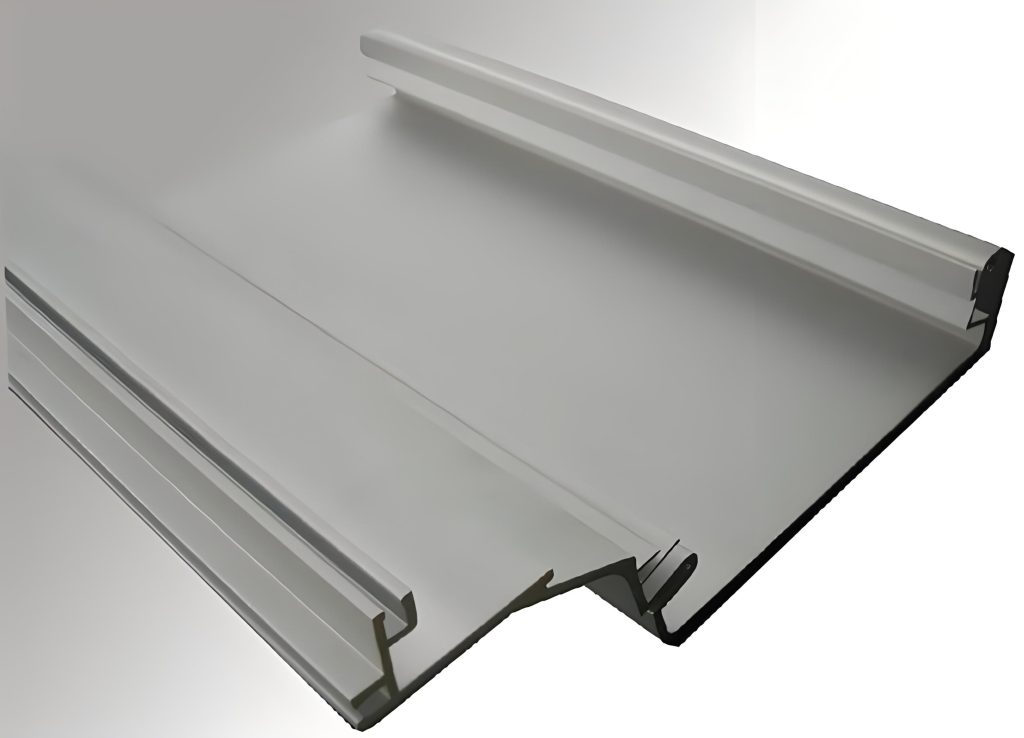

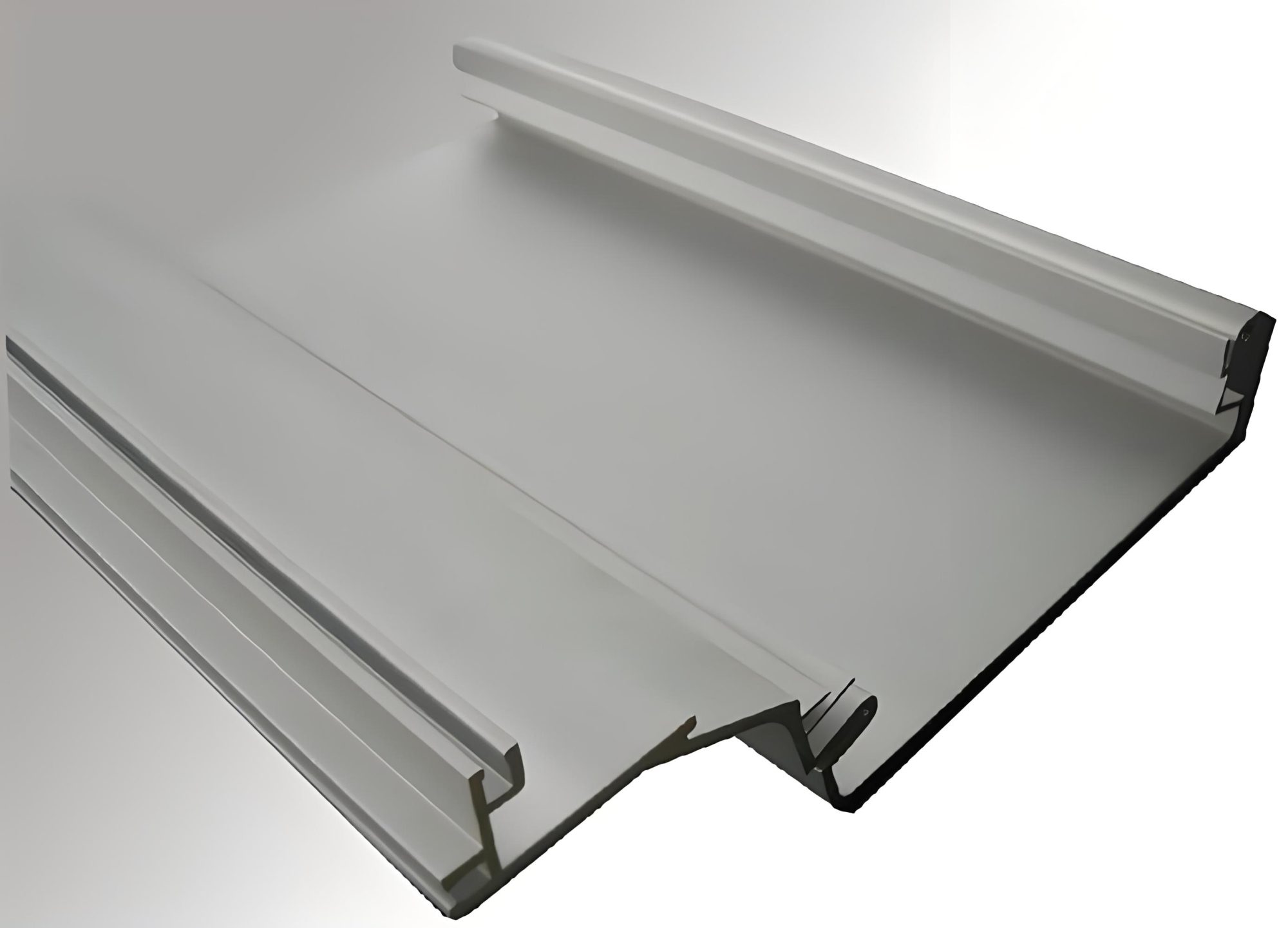

Automobile Structural Parts: Aluminum profiles find extensive use in manufacturing body structural parts such as doors, roofs, and body panels, ensuring weight reduction without compromising structural integrity.

Automobile Chassis Parts: From suspension systems to steering and braking components, aluminum profiles enhance vehicle handling performance and comfort while reducing overall weight.

Automotive Power System Components: Aluminum profiles contribute to the development of engine and transmission system components, reducing mass and improving energy efficiency.

Appearance Decoration: Aluminum profiles are utilized for exterior decoration, enhancing the aesthetics of vehicles through features like hoods, doors, and fenders.

Advantages of Aluminum Profiles in Automobile Manufacturing

- Lightweight: Aluminum profiles significantly reduce vehicle weight, leading to improved fuel efficiency and reduced carbon emissions, in line with environmental regulations.

- High Strength: Despite their lightweight nature, aluminum profiles offer exceptional strength and stiffness, meeting safety requirements for vehicle structural parts.

- Corrosion Resistance: With excellent corrosion resistance, aluminum profiles ensure the longevity and durability of vehicles, even in harsh environmental conditions.

- Easy Processing and Customization: Aluminum profiles can be easily customized to meet the specific requirements of automobile manufacturers, enhancing production efficiency.

- Recyclability: Aluminum profiles are fully recyclable, aligning with sustainability goals and contributing to the circular economy.

Trends and Future of Aluminum Profiles in the Automotive Industry

The automotive industry is witnessing a shift towards sustainable practices and technological advancements. As environmental awareness grows, manufacturers are increasingly turning to aluminum profiles to meet stringent regulations while driving innovation. Future developments are expected to focus on further reducing carbon emissions, enhancing efficiency, and promoting sustainable manufacturing practices.

Conclusion

In conclusion, aluminum profiles stand as a cornerstone of automotive manufacturing, offering a winning combination of strength, lightweight construction, and environmental sustainability. As the industry continues to evolve, aluminum profiles will play an increasingly vital role in shaping the future of mobility, driving innovation, and paving the way towards a greener automotive landscape.