Introduction

In the world of construction, the quality of materials is paramount, and this is especially true for aluminum alloy profiles. These profiles play a crucial role in the structural integrity and aesthetic appeal of buildings. Understanding how to identify and maintain high-quality aluminum profiles is key to ensuring the longevity and safety of construction projects.

Checking the Factory Certificate

The first step in assessing quality is examining the product’s factory certificate. This document contains vital information such as the factory date, specifications, technical conditions, company name, and production license number. These details offer initial insight into the product’s conformity to industry standards.

Importance of Wall Thickness

Wall thickness in aluminum profiles is a critical indicator of quality, particularly for materials used in doors and windows. The thickness should not be less than 1.2mm, as it directly impacts the strength and durability of the profile in architectural applications.

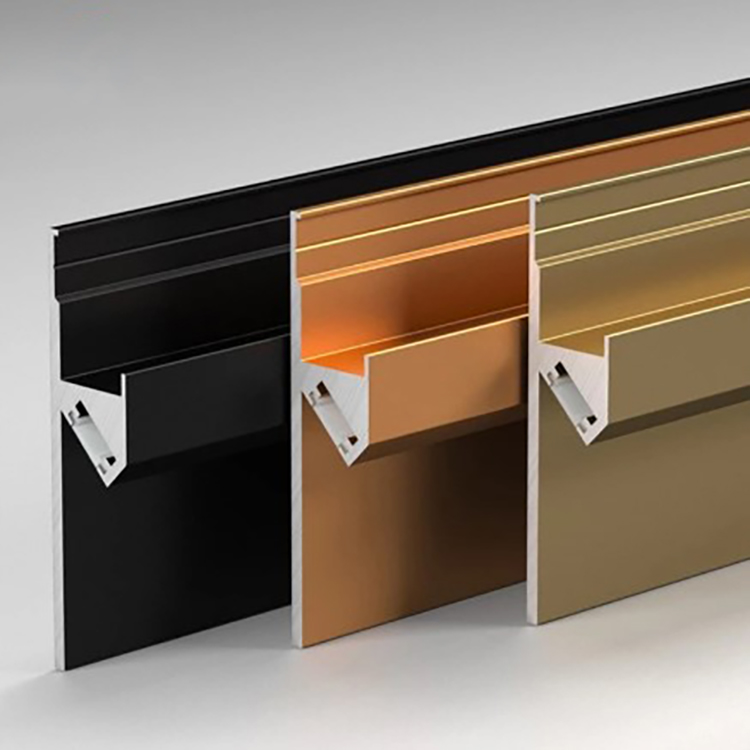

Examining Surface Condition

high-quality aluminum profile should have a bright, glossy surface with no visible defects such as scratches or bubbles. Careful observation of the surface condition can reveal much about the manufacturing quality and finish of the product.

Surface Coating Thickness

The thickness of surface coatings on aluminum profiles is another essential aspect of quality. For anodized products, the film thickness should be no less than 10 μm; for electrophoretic painted products, no less than 17 μm; for powder-sprayed products, between 40-120 μm; and for fluorocarbon paint spray products, above the second coat and not lower than 30μm.

Best Practices for Daily Maintenance

Maintaining the quality of aluminum profiles requires appropriate daily care. It is advisable to use soft tools such as cotton gauze and cloth for cleaning, avoiding hard brushes that can damage the surface.

Appropriate Cleaning Agents

For cleaning, water, detergent, and soap are safe options. However, it’s crucial to steer clear of other organic substances that might harm the aluminum’s surface.

Special Considerations for Coastal Areas

For buildings in coastal areas, where corrosion is a significant concern, choosing electrophoretic painted, powder sprayed, or fluorocarbon sprayed aluminum profiles is advisable due to their enhanced corrosion resistance.

Conclusion

Identifying and maintaining the quality of building aluminum profiles is crucial for the success and safety of construction projects. By following these guidelines, constructors and architects can ensure that their aluminum materials meet the highest standards of quality, providing durability, strength, and aesthetic appeal for years to come.