Introduction

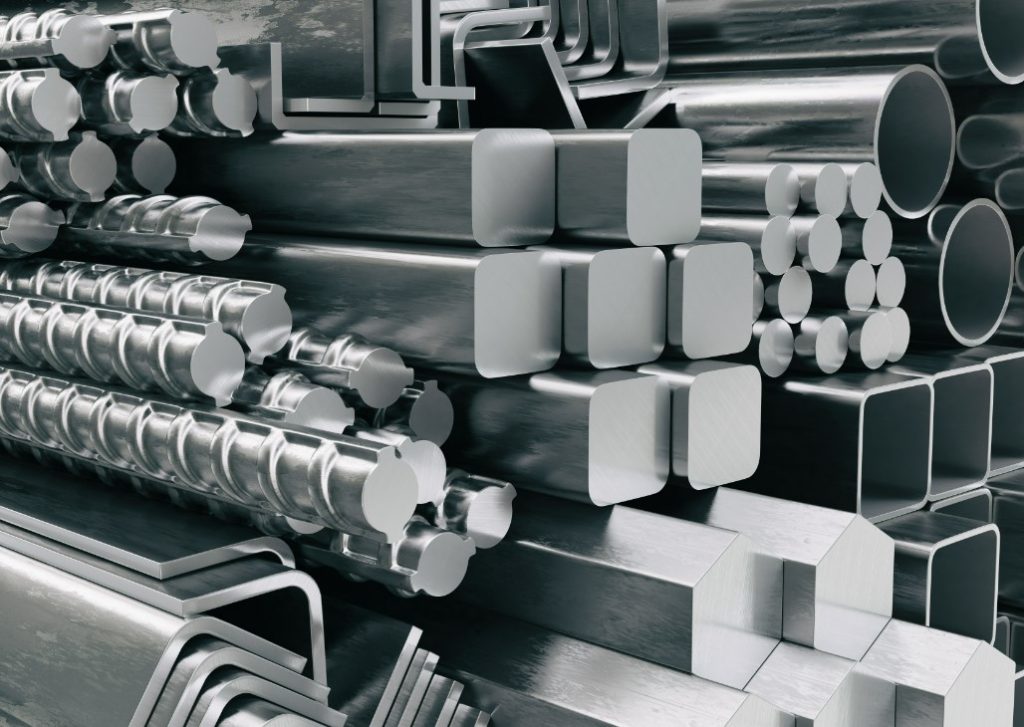

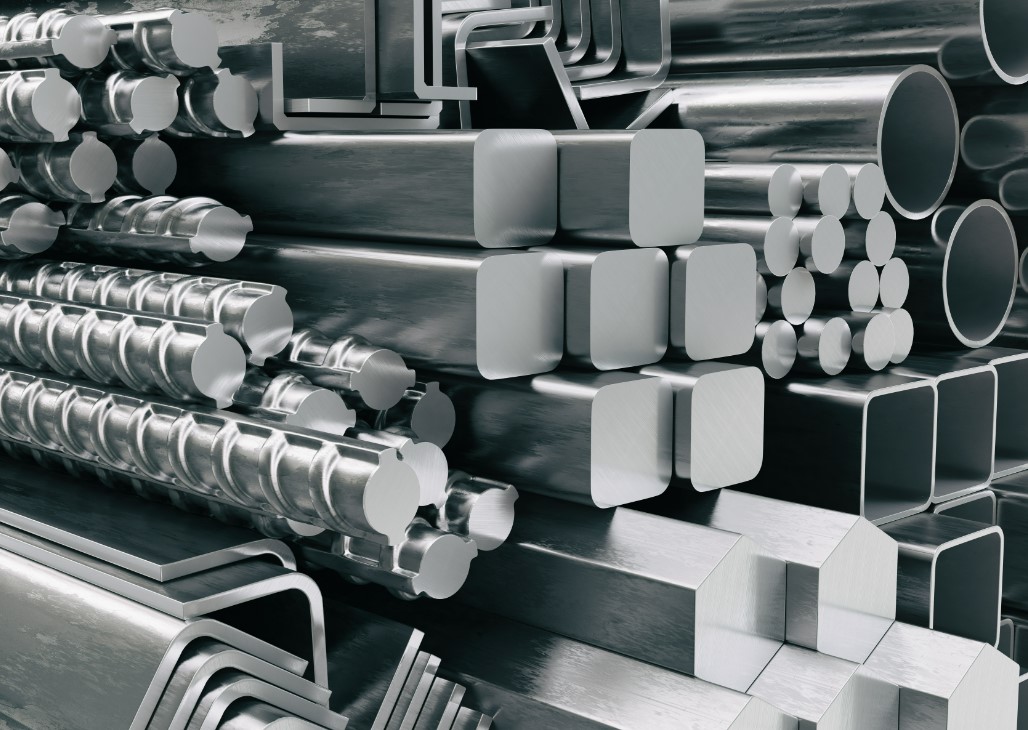

Special-shaped aluminum materials offer a plethora of benefits, including corrosion resistance, lightweight construction, and high strength, making them indispensable in various industries. However, to fully realize their potential, these materials undergo deep processing techniques, enabling their application in a wide range of fields.

Methods of Deep Processing

Special-shaped aluminum undergoes several methods of deep processing to meet the specific needs of different industries. Cutting, stamping, welding, and bending are among the most common techniques employed to shape and refine the material according to desired specifications.

Applications in Various Fields

In the construction industry, special-shaped aluminum finds its place in window frames, door frames, and curtain walls, offering lightweight alternatives to traditional materials without compromising strength. Similarly, in transportation, aerospace, and electronics sectors, the material’s versatility shines through, enhancing fuel efficiency, speed, and heat dissipation in automobiles, aircraft, and electronic devices.

Future Prospects

The continuous evolution of deep processing techniques for special-shaped aluminum holds promising prospects for innovation and advancement across industries. As technology progresses, the material’s adaptability and utility are expected to expand further, opening new avenues for development and growth.

Conclusion

The deep processing of special-shaped aluminum materials paves the way for their widespread application across diverse industries, driving innovation and progress. With its unmatched properties and endless possibilities, special-shaped aluminum continues to shape the future of modern manufacturing and construction.