Introduction to Aluminum Profile Factories

Aluminum profile factories play a pivotal role in modern manufacturing, producing essential components for various industries. These factories specialize in aluminum extrusion, a process that transforms aluminum alloys into diverse profiles with a multitude of applications. Aluminum profiles, known for their strength, light weight, and versatility, are integral to sectors ranging from construction to industrial machinery. This introduction will provide an overview of aluminum extrusion and the significance of aluminum profile factories in the manufacturing landscape, setting the stage for a deeper exploration into their processes and products.

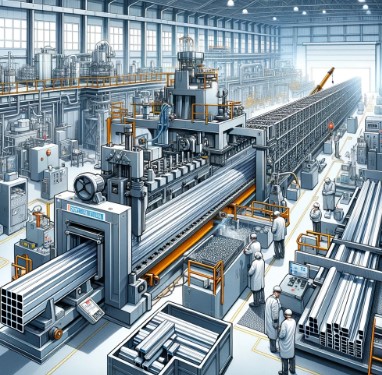

Manufacturing Processes in Aluminum Profile Factories

The manufacturing process in aluminum profile factories is a testament to technological advancement and engineering precision. It begins with aluminum billets, which are heated and then forced through a die to create various shapes and forms. This process, known as extrusion, is central to producing aluminum profiles. The design and temperature control of the dies are critical for achieving the desired profile with high accuracy and quality. These processes underscore the technological sophistication inherent in aluminum profile factories, showcasing their ability to produce a wide range of profiles for diverse applications.

Types of Aluminum Profiles and Their Applications

Aluminum profile factories produce a vast array of profiles, each serving specific applications across multiple industries. Standard profiles include I beams, angle brackets, and tubes, commonly used in construction and structural applications. Custom profiles are tailored to meet unique requirements, often designed in collaboration with clients to ensure precise specifications are met. These profiles find their place in specialized industrial applications, highlighting the adaptability and versatility of aluminum as a material. The diverse range of profiles produced in aluminum profile factories demonstrates their critical role in various sectors, from construction to complex machinery.

Advancements in Aluminum Profile Manufacturing

Innovation and technological advancements are the hallmarks of modern aluminum profile factories. These advancements encompass improvements in extrusion techniques, allowing for more complex and precise profiles. The ability to customize profiles has also seen significant progress, enabling manufacturers to cater to specialized and niche market demands. These innovations not only enhance the capabilities of aluminum profile factories but also contribute to the broader field of manufacturing, driving efficiency and expanding the potential applications of aluminum profiles.

Selecting the Right Aluminum Profile Factory

Choosing the right aluminum profile factory is crucial for ensuring quality and meeting specific project requirements. Factors such as the factory’s production capabilities, experience in custom profile design, and commitment to quality play a vital role in this decision. The selection process should focus on identifying manufacturers that can provide the required precision, customization options, and consistent quality. This choice impacts the overall success of projects that rely on aluminum profiles, making the selection of the right factory a significant step in the procurement process.

Conclusion

The exploration of aluminum profile factories reveals their integral role in modern manufacturing. With advancements in technology and processes, these factories are poised to continue their evolution, meeting the growing demands for high-quality, customized aluminum profiles. The future of aluminum profile manufacturing looks towards increased sustainability and efficiency, ensuring that these factories remain at the forefront of industrial production and innovation.

FAQs

Q1: What is the primary process used in aluminum profile factories?

A1: The primary process used in aluminum profile factories is extrusion, where aluminum billets are heated and forced through a die to create various shapes and forms.

Q2: What are some common types of aluminum profiles produced in factories?

A2: Common types of aluminum profiles include standard profiles like I beams, angle brackets, and tubes, as well as custom profiles designed for specific applications.

Q3: What factors are important when selecting an aluminum profile factory?

A3: Important factors include the factory’s production capabilities, experience in custom profile design, quality assurance, and ability to meet specific project requirements.

Q4: How do advancements in technology impact aluminum profile factories?

A4: Technological advancements in aluminum profile factories enhance extrusion techniques, improve precision in profile design, and enable the production of more complex profiles, meeting diverse industry needs.

Q5: What role do aluminum profile factories play in modern manufacturing?

A5: Aluminum profile factories are integral to modern manufacturing, supplying essential components for various industries such as construction, machinery, and specialized industrial applications.