Introduction

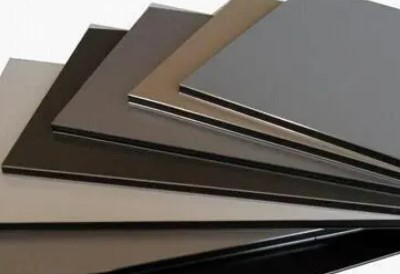

Aluminum, known for its versatility and widespread use, is a staple in both industrial applications and everyday life. Among its various forms, aluminum plates stand out due to their unique properties, making them essential in numerous fields. This article delves into the advantages and disadvantages of aluminum plates, highlighting their applications and providing guidance on selecting the right material for specific needs.

Advantages of Aluminum Plates

Lightweight Properties

One of the most significant advantages of aluminum plates is their lightweight nature. With a density much lower than many other metals, aluminum plates are ideal for applications where weight reduction is crucial. This characteristic is particularly beneficial in industries such as aerospace and automotive manufacturing, where reducing the overall weight of components can lead to improved performance and fuel efficiency.

Good Processing Properties

Aluminum plates boast excellent processing capabilities, allowing them to be rolled, drawn, and shaped into various forms and specifications. This versatility makes aluminum plates indispensable in industrial manufacturing, where custom shapes and sizes are often required. From intricate parts in machinery to large structural components, aluminum’s malleability ensures it meets diverse industrial demands.

Excellent Thermal Conductivity

Another notable advantage of aluminum plates is their superior thermal conductivity. This property is essential for products that require efficient heat dissipation, such as radiators and heat exchangers. In these applications, aluminum plates help maintain optimal operating temperatures, thereby enhancing the performance and longevity of the equipment.

Corrosion Resistance

Aluminum’s natural corrosion resistance is a major benefit, especially in environments exposed to moisture and chemicals. Aluminum plates are commonly used in the production of chemical containers and other products that must withstand corrosive conditions. This resistance ensures durability and longevity, reducing the need for frequent replacements.

Disadvantages of Aluminum Plates

Lower Strength Compared to Special Engineering Materials

While aluminum plates offer numerous advantages, they also have some limitations. One of the primary drawbacks is their lower strength compared to certain specialized engineering materials. In applications where high strength is critical, such as in structural components of buildings or heavy machinery, alternative materials like steel might be preferred.

Higher Cost

The cost of aluminum plates can be relatively high, which might be a disadvantage in projects with strict budget constraints. While the material’s benefits can justify the expense in many cases, it’s important to consider the overall cost-effectiveness, especially for large-scale projects where material costs can significantly impact the budget.

Practical Applications and Considerations

Aluminum plates are most beneficial in applications where their unique properties provide a significant advantage. For instance, their lightweight nature is invaluable in the aerospace and automotive industries, while their thermal conductivity is crucial in electronics and heating applications. However, when selecting materials, it’s essential to weigh the advantages against the disadvantages. Consider the specific requirements of your project, including the need for strength, cost constraints, and environmental factors.

Conclusion

Aluminum plates are a versatile and widely used material with numerous advantages, including lightweight properties, excellent processing capabilities, superior thermal conductivity, and corrosion resistance. However, they also have limitations such as lower strength and higher cost. By carefully considering these factors, you can make informed decisions about whether aluminum plates are the right choice for your specific needs. Their unique properties make them a valuable material in many applications, ensuring they remain a staple in both industry and daily life.