Introduction

Industrial materials have revolutionized manufacturing across various sectors, offering unparalleled advantages in simplicity, recyclability, and precision. In this article, we delve into the widespread adoption and significance of industrial materials, with a special focus on the indispensable role of aluminum in modern manufacturing processes.

Advantages of Industrial Materials

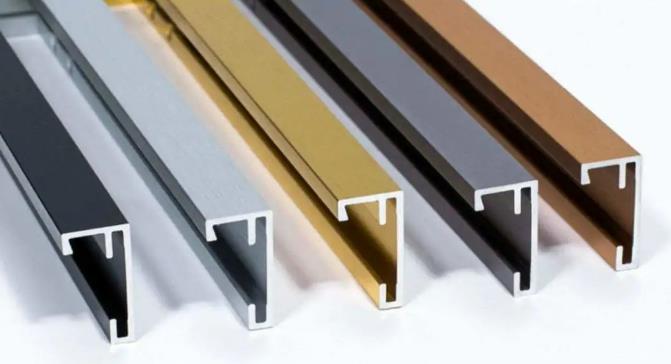

Industrial materials, including aluminum, offer several key advantages over traditional manufacturing materials. Their simplified production processes streamline assembly line operations, reduce labor costs, and save valuable time. Additionally, their recyclability and reusability contribute to environmental sustainability while maintaining high assembly precision, ensuring optimal product quality.

Application of Industrial Materials in Different Industries

The versatility of industrial materials extends across diverse industries, including aerospace, transportation, and packaging. In aerospace, industrial materials such as aluminum are used to manufacture aircraft components with exceptional strength-to-weight ratios. Similarly, in transportation, aluminum alloys play a crucial role in producing lightweight yet durable automotive parts and subway structures. Furthermore, in the packaging industry, aluminum serves as a preferred choice for metal packaging materials, offering superior protection and preservation for various consumer goods.

Aluminum’s Role in Industrial Materials

Aluminum stands out as a cornerstone of industrial materials, thanks to its remarkable properties and versatility. Its lightweight nature, corrosion resistance, and malleability make it an ideal choice for a wide range of applications, from aircraft skins and automobile components to packaging foils and structural frames. As industries continue to innovate and adapt to evolving demands, aluminum remains at the forefront of modern manufacturing, driving efficiency, sustainability, and quality.

Conclusion

Industrial materials, with aluminum leading the way, have revolutionized modern manufacturing, offering unparalleled advantages in simplicity, sustainability, and precision. As industries continue to embrace the versatility of industrial materials, the role of aluminum in shaping the future of manufacturing processes becomes increasingly vital. Embrace the transformative power of industrial materials and witness the evolution of manufacturing in the 21st century.