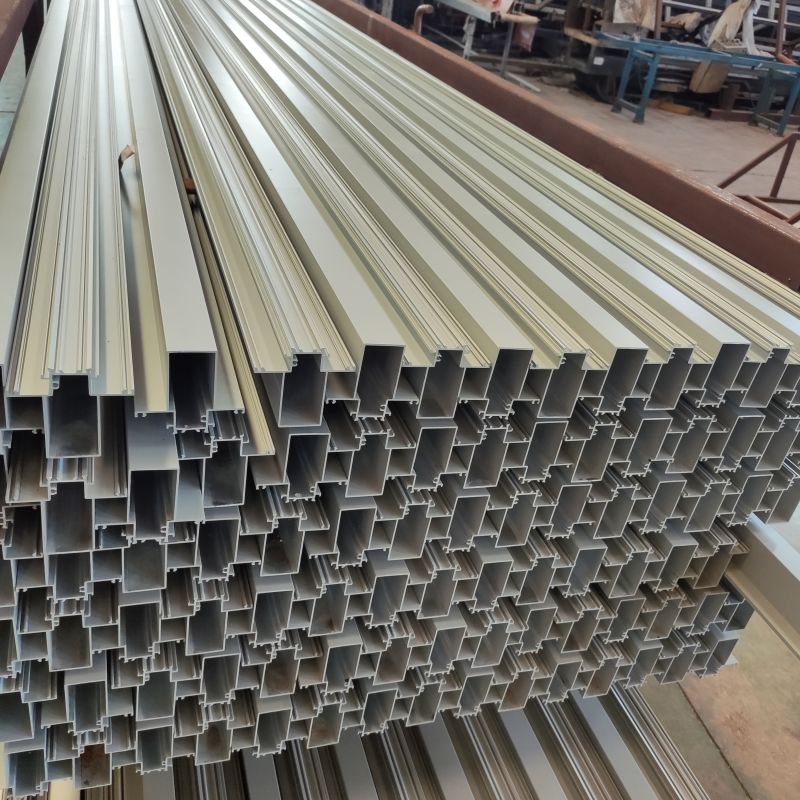

Introduction

Bending in aluminum profile processing can lead to costly errors and compromised quality. Understanding the causes of bending and implementing proper techniques is crucial for achieving precise and flawless aluminum profiles.

Understanding Straightening Process

The straightening process is a critical step in aluminum profile processing, but improper techniques can result in bending. It’s essential to apply the right amount of force during straightening to avoid deformation, tightening, or orange peeling of the profile.

Kneading and Framing Aluminum Profiles

Kneading and framing play significant roles in ensuring the stability and integrity of aluminum profiles. Attention to detail is key, particularly regarding material size and type. Proper framing techniques can prevent bending and ensure the profile’s structural integrity.

Considerations for Handling Aged Aluminum Profiles

Aged aluminum profiles present unique challenges due to their increased susceptibility to bending. Careful handling is required to prevent distortion or bending during lifting and storage. Maintaining stability and avoiding sudden movements are essential when handling aged profiles.

Conclusion

Preventing bending in aluminum profile processing requires a combination of knowledge, skill, and attention to detail. By mastering the straightening process, framing techniques, and proper handling of aged profiles, fabricators can ensure the production of high-quality aluminum profiles free from defects and bending.