Introduction

Aluminum is undeniably a versatile metal, finding its applications in various industries, from automotive to construction. As the demand for this metal surges, ensuring the top-notch quality of aluminum profiles becomes paramount.

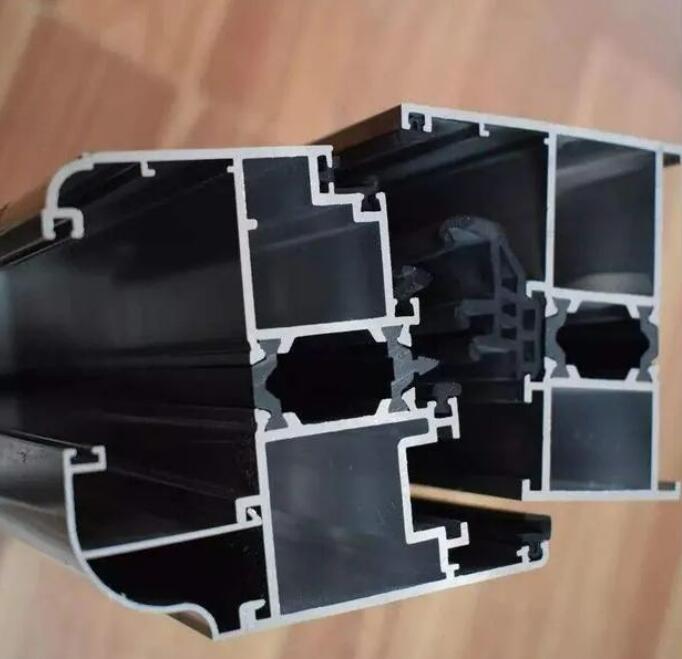

Understanding Hot Extruded Aluminum Profiles

The manufacturing process of hot extruded aluminum profiles is intricate. The quality of mold polishing and adherence to optimal process conditions can significantly influence the outcome. One of the immediate tell-tale signs of this influence is the surface defects. Commonly, profiles may exhibit rough lines, dark bands, bright bands, and even raised bones among other defects. Recognizing and rectifying these at the outset can be a game-changer.

Common Defects in Aluminum Extrusion Production

Extrusion production is where the aluminum takes its shape. And like any process, it’s prone to defects. While some, like bending or slag inclusion, are quite straightforward to spot, others can be more elusive, demanding a keener inspection eye.

Initial Inspection of Aluminum Profiles

Quality assurance begins right at the start. As soon as the mold is operational and the first 2-3 rods are extruded, an initial surface quality judgment is made. This preliminary assessment acts as a foundation for subsequent quality checks, ensuring only the finest aluminum profiles make it to the next stage.

Methods to Assess Surface Quality Defects

In the world of aluminum profile manufacturing, early detection of defects is gold. Here’s a look at five tried-and-tested methods professionals swear by:

- Hand touch method: A hands-on approach, literally. By touching the profile’s surface or using fingernails to identify any inconsistencies, experts can get an intuitive feel of the material.

- Pencil scratch technique: Simple yet effective. Running a pencil across the aluminum profile can reveal the presence of thick lines, especially on oxidized materials.

- Spray paint test: A method that uses automatic spray paint to simulate the final look of the product, helping in spotting scratches or any surface irregularities.

- Alkali washing procedure: Immersing a sample section in an alkali solution can unveil defects like color separation or mold welding lines, crucial for high-end applications.

- Surface polishing: By polishing a section of the base material, even the subtlest defects, which might be overlooked by other methods, come to light.

Continued Vigilance Post Initial Inspection

Approving the first piece doesn’t mean the end of the road. Anomalies can crop up even during the subsequent stages of the extrusion process. It’s imperative to constantly calibrate the assessment methods based on the quality requirements of each order.

Conclusion

In the bustling world of aluminum, where demand meets supply, ensuring impeccable quality is non-negotiable. With a meticulous approach to quality assessment, the industry can continue to uphold the high standards that aluminum, the metal of the future, truly deserves.