Introduction to Aluminum Tube Production Techniques

Aluminum tubes are essential components in various industries, from construction to automotive and aerospace. Understanding the production techniques behind aluminum tubes is crucial for achieving optimal quality and performance. Let’s delve into the processes involved, challenges faced, and measures taken to ensure quality in aluminum tube production.

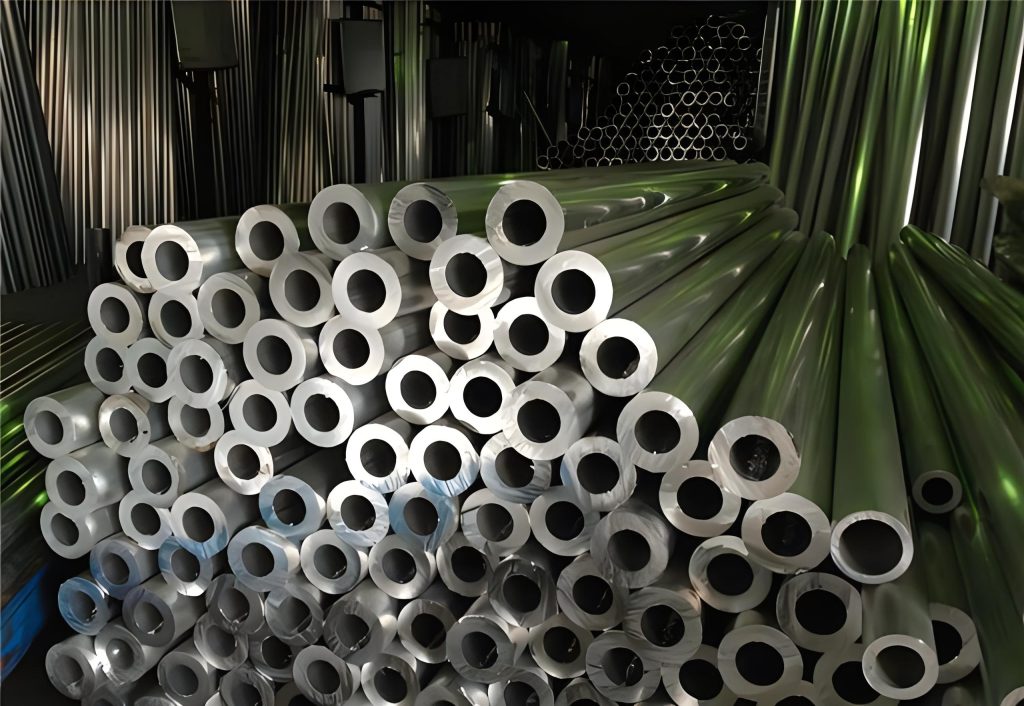

Extrusion Process for Aluminum Tube Production

The extrusion process is a common method used for producing aluminum tubes. This process involves feeding heated aluminum blocks into an extrusion machine, where they are pushed through a die to obtain the desired cross-sectional shape and size. Extrusion deformation during this process improves the mechanical properties of the aluminum, making it ideal for various applications.

Seamless Aluminum Tube Production

Seamless aluminum tubes offer superior strength and durability, making them highly desirable in industries requiring precision and reliability. Production methods for seamless tubes require strict precision and control to ensure high-quality results. Whether through hot extrusion or cold stretching, seamless aluminum tubes demand meticulous attention to detail to meet industry standards.

Quality Control Measures

Maintaining quality in aluminum tube production involves addressing various factors, such as preventing blisters in seamless tubes and ensuring cleanliness throughout the production process. The presence of blisters can compromise the integrity of the tube, highlighting the importance of using clean aluminum rods and controlling environmental conditions. Additionally, cleaning solutions with appropriate sodium hydroxide content play a crucial role in preventing defects and ensuring quality.

Conclusion

Mastering aluminum tube production requires a deep understanding of the extrusion process, seamless tube production methods, and quality control measures. By addressing challenges and implementing rigorous quality control measures, manufacturers can produce high-quality aluminum tubes that meet industry standards and exceed customer expectations. As technology advances and industry demands evolve, continuous improvement and innovation will play key roles in shaping the future of aluminum tube production.