Introduction

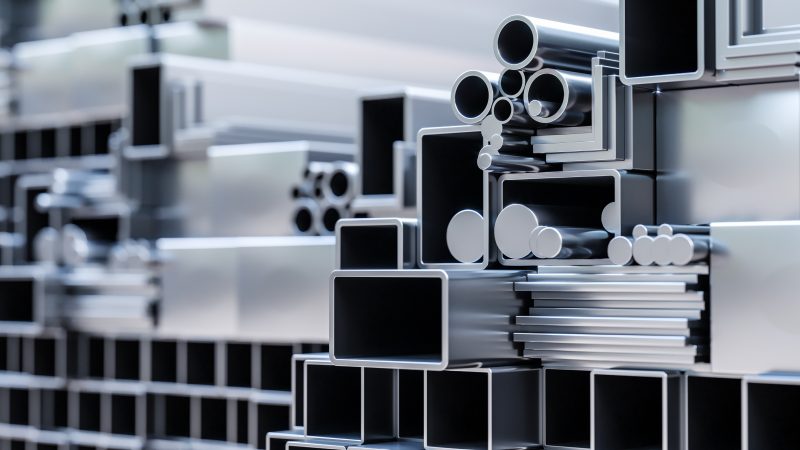

Aluminum profile frames are a cornerstone in various industries, revered for their versatility and utility. However, customizing these frames is not a task to be taken lightly, as it requires precision and a deep understanding of customer needs to avoid common problems like instability and inadequate load-bearing.

Meeting Actual Customer Needs

The foremost step in aluminum profile frame customization is to grasp and fulfill the actual needs of the customers. This process starts with a thorough consultation to understand specific requirements, ensuring that the customization aligns perfectly with the client’s vision and practical needs.

Designing with a Reasonable Structure

A well-thought-out structural design is crucial for any aluminum profile frame, whether it involves multiple layers or a single one. A deep understanding of the frame’s internal structure and the specific role of each component is essential to create a functional and reliable product.

Compliance with Ergonomics

Ergonomic design is paramount in ensuring that aluminum profile frames serve their purpose effectively while ensuring the safety and ease of use for both machinery and personnel. This integration of ergonomic principles is vital for the overall effectiveness of the frame.

Ensuring Load-Bearing Capacity and Stability

The selection of appropriate profile specifications and connection methods is critical to ensure the frame’s load-bearing capacity and stability. This careful consideration in the design phase prevents future problems such as shaking or collapsing, ensuring the frame’s longevity and reliability.

The Importance of Scientific Drawings

Accurate and detailed drawings play a pivotal role in the customization of aluminum profile frames. These scientific drawings serve as a blueprint, reducing processing errors and material waste, and ensuring that every aspect of the frame is precisely as required.

Controlling Accuracy and Reducing Errors

Precision is key in customization, and controlling accuracy errors is a vital part of the process. Understanding the common errors such as straightness, twisting, flatness, and dimensional discrepancies is essential to deliver a high-quality, customized product that meets all expectations.

Conclusion

Mastering aluminum profile frame customization requires a blend of technical knowledge, precision, and customer-centric approach. By focusing on these key aspects, manufacturers can ensure client satisfaction through high-quality, custom-built frames that meet specific needs and stand the test of time.