Introduction:

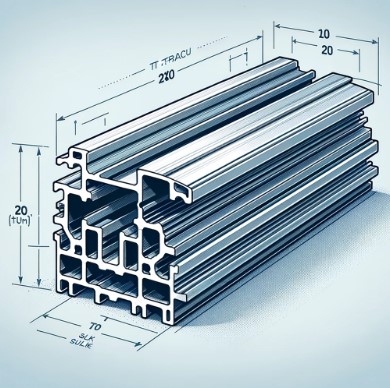

In the realm of aluminum profiles, surface damage poses a common challenge that demands attention. This article delves into the root causes of surface damage and unveils effective solutions crucial for maintaining the high standards of aluminum products.

Causes of Surface Damage:

From debris and segregation on the ingot surface to issues in the mold cavity and excessive speed during handling, we dissect the multifaceted causes of surface damage in aluminum profiles. Understanding these factors is key to implementing effective preventive measures.

Solutions to Surface Damage:

Addressing these challenges requires a comprehensive approach. We explore solutions such as strengthening ingot quality control, improving mold quality through regular nitriding, and implementing careful handling practices during production and transportation.

Conclusion:

Preserving the excellence of aluminum profiles necessitates proactive measures. By understanding and implementing these solutions, manufacturers can ensure the longevity and aesthetic appeal of their aluminum products. Surface damage can be mitigated, and the journey towards pristine aluminum profiles begins with a commitment to quality and precision.