Introduction

In the ever-evolving automotive industry, the eCV1 stands out as a beacon of innovation and sustainability. This electric, light commercial vehicle, a product of the collaboration between Hydro and WEVC, is set to redefine transportation standards. Its use of recycled, low-carbon aluminium for the chassis is a game-changer in the industry, underscoring a commitment to environmentally conscious practices.

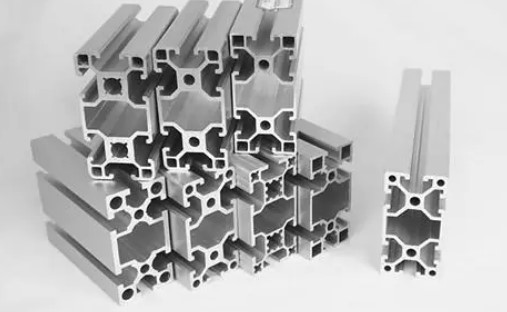

The Role of Aluminium in eCV1

Aluminium plays a pivotal role in the design and functionality of the eCV1. The vehicle’s chassis utilizes seven different aluminium extrusions, integrated into Hydro’s patented electric vehicle connection system. This approach significantly reduces the vehicle’s weight, enhancing its efficiency and performance. By opting for recycled, low-carbon aluminium, Hydro and WEVC are not just building a vehicle; they are crafting a statement on sustainable innovation.

Environmental Impact and Sustainability

The eCV1’s environmental footprint is notably lower than its competitors, thanks in large part to the use of recycled aluminium. This material, comprising at least 35% post-consumer scrap, is sourced from various channels, including old windows, car parts, and beverage cans. The carbon footprint per kg of this aluminium is exceptionally low, making the eCV1 a leader in sustainable vehicle production. This commitment to the environment is further evidenced by the independent certification of Hydro’s environmental data, providing transparency and accountability.

Production and Recycling Processes

Set to begin production in 2025, the eCV1 represents a significant step forward in sustainable vehicle manufacturing. Hydro’s Tibshelf plant plays a crucial role in this process, specializing in the recycling of aluminium and casting low-carbon extrusion billets. The plant’s proximity to the extrusion site facilitates a closed-loop recycling system, minimizing waste and maximizing efficiency.

Future of Aluminium in Automotive Industry

The automotive industry is witnessing a shift towards the use of extruded aluminium components. This trend is driven by the need to balance vehicle weight with safety standards, especially in electric vehicles where battery weight is a significant factor. Aluminium, particularly recycled and low-carbon variants, is increasingly becoming the material of choice due to its sustainability and performance advantages.

Conclusion

The eCV1 is more than just a vehicle; it’s a testament to the possibilities of sustainable automotive design. Hydro’s approach, from its innovative use of recycled aluminium to its commitment to closed-loop recycling, sets a new standard in the industry. As we look towards a future where environmental considerations are paramount, the eCV1 stands as a model of what is achievable when innovation meets sustainability.