Introduction

In the realm of manufacturing and construction, aluminum stands as a cornerstone material, prized for its strength, versatility, and lightweight nature. Within this broad spectrum, industrial aluminum profiles occupy a critical niche, offering tailored solutions for a myriad of applications. This guide demystifies the process of selecting the perfect aluminum profile for your industrial needs, spotlighting the renowned 6063-T5 series among others.

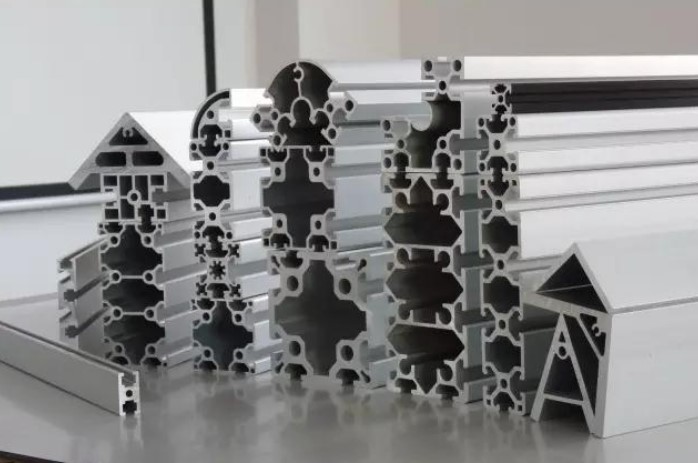

Understanding Industrial Aluminum Profiles

Industrial aluminum profiles are the backbone of many manufacturing processes, providing structural support and functional utility across industries. The 6063-T5 series, in particular, is celebrated for its optimal balance of strength, ductility, and finishing properties, making it a go-to choice for many.

Criteria for Selection

Strength and Load-Bearing Capacity

The integrity of an industrial aluminum profile is measured by its strength. This encompasses tensile strength, compressive strength, and yield resistance—fundamental attributes that ensure the profile can withstand the rigors of its intended application. Selecting a profile with adequate strength is crucial, necessitating a careful assessment of load-bearing requirements and consultation with manufacturers for precise calculations.

Usage Environment

The operational environment is a decisive factor in selection. Industrial aluminum profiles undergo various surface treatments to enhance their resistance to wear, corrosion, high temperatures, and adverse weather. Whether your application demands the resilience of the 6063-T5 model in harsh conditions or a standard profile suffices, understanding the environment is key to an informed choice.

Usage Requirements

Beyond strength and environment, the specific requirements of your project guide the selection process. This includes considering the load-bearing capacity, mechanical properties, and the overall design of the equipment framework. Manufacturers provide valuable insights and parameters, aiding in the selection of the most suitable profile and accessories for your needs.

Appearance Requirements

Aesthetic considerations also play a role, with options like electrolytic coloring, electroplating, and powder spraying available to customize the profile’s appearance. Balancing aesthetic desires with budget constraints is essential, as different processing methods impact the cost and final look of the profile.

Practical Selection Guide

Armed with knowledge of strength, environment, usage, and appearance requirements, selecting the right industrial aluminum profile becomes a structured and strategic process. Engaging with manufacturers, leveraging their expertise, and referring to selection manuals can streamline decision-making, ensuring a match that meets both performance and aesthetic criteria.

Conclusion

Choosing the right industrial aluminum profile is a nuanced process that balances numerous factors, from mechanical properties to environmental conditions and aesthetic preferences. By adhering to the criteria outlined in this guide, you can navigate the selection process with confidence, securing a solution that enhances the value and efficiency of your industrial applications.