Introduction

The integration of aluminum profiles in shower industrial design marks a significant leap forward in both functionality and aesthetics. As we delve into the nuances of shower component materials, the shift towards aluminum stands out for its innovative approach to enhancing user experience and product longevity.

Innovation in Shower Rods with Aluminum Profiles

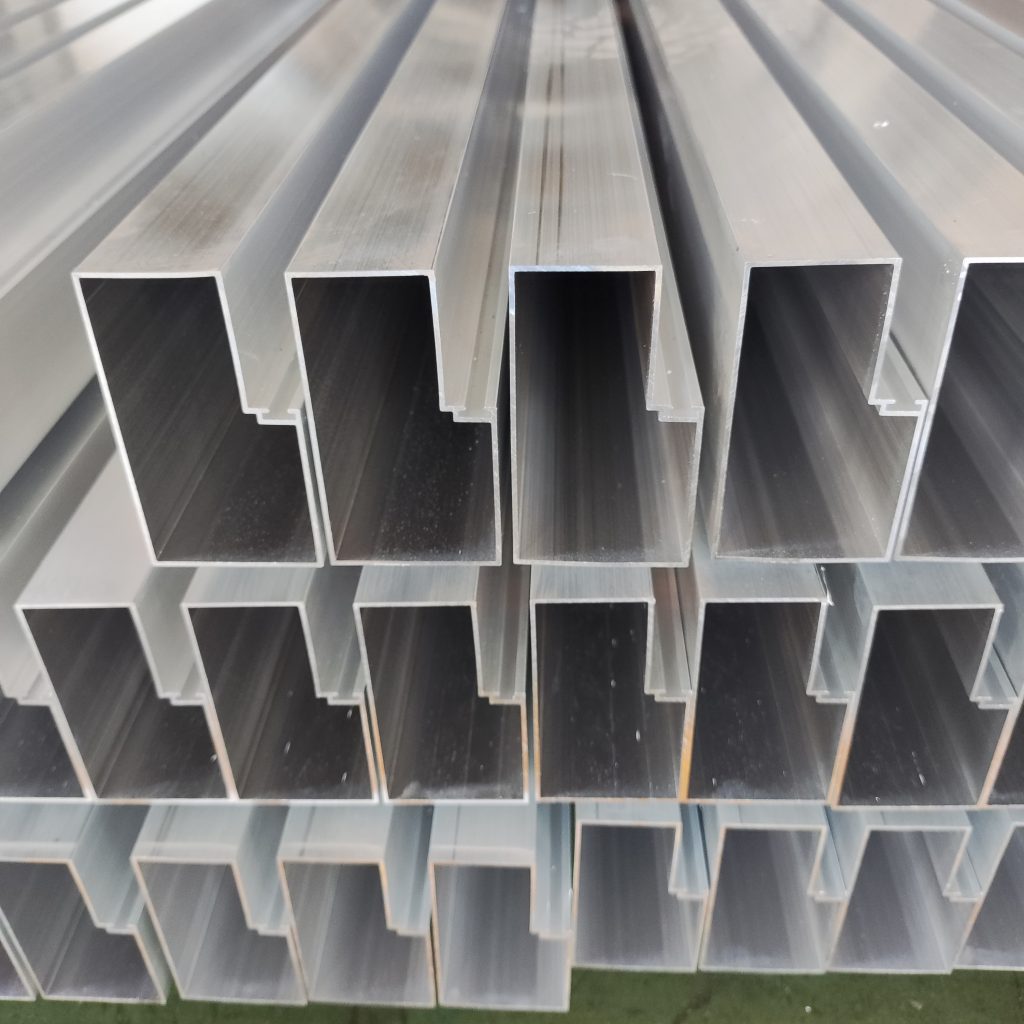

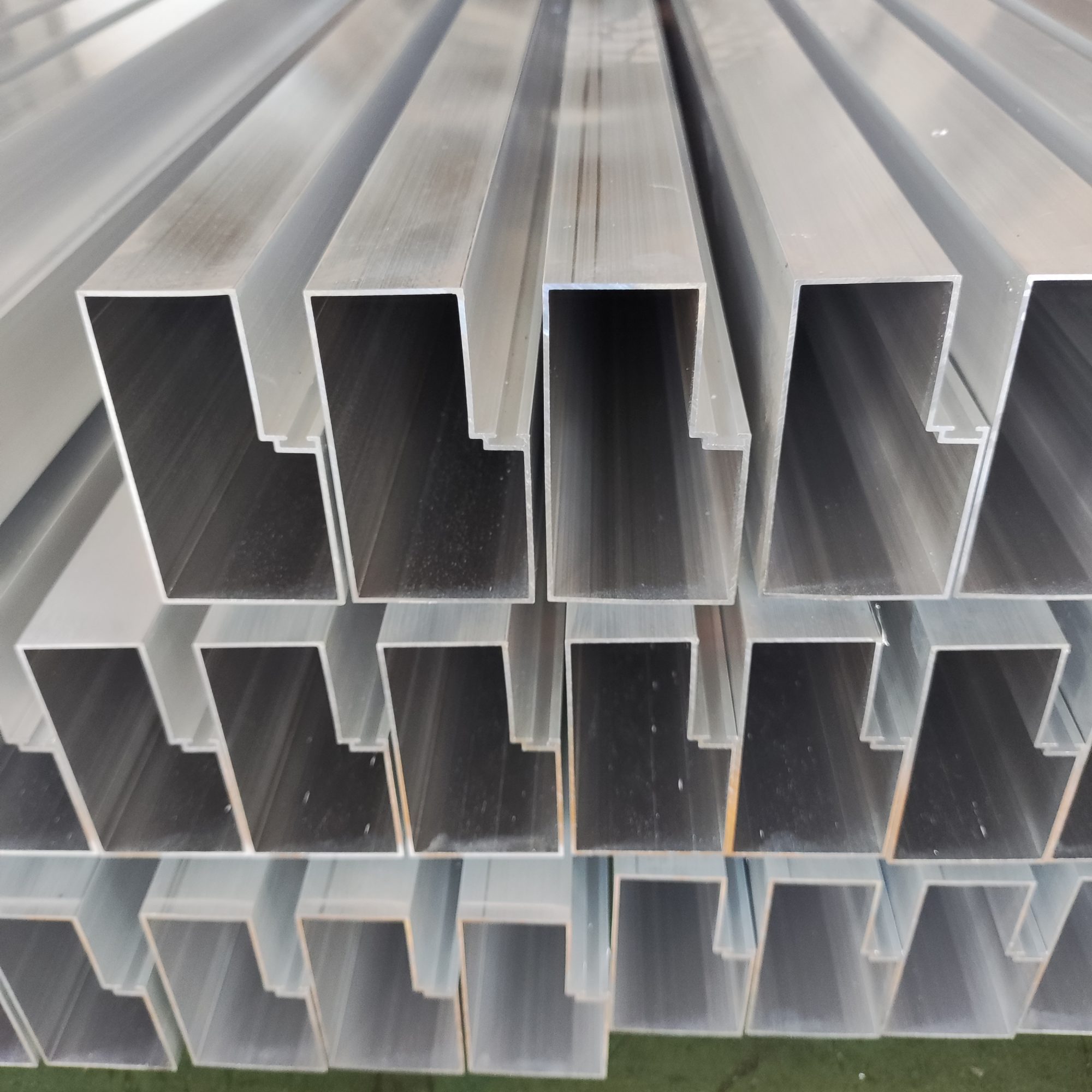

Traditionally, shower rods have been crafted from materials like copper, known for their round, coiled designs. However, the flat and square requirements of contemporary shower designs demand more flexibility, a challenge adeptly met by aluminum profiles. The extrusion process characteristic of aluminum allows for complex cross-sections, facilitating sleek, flat shower rods with integrated waterways and slideways. This not only enhances the visual appeal but also significantly improves functionality.

In the realm of integrated lifting showers, aluminum’s versatility shines, supporting a “less is more” design ethos. The ability to house an infinite lifting module, water passage, and customizable spray options within the same aluminum profile demonstrates a significant advancement in user-centered design.

The Advantages of Aluminum Profiles in Shower Faucets

Shifting to shower faucets, the adoption of extruded aluminum technology overcomes the limitations of conventional plastic injection molding. Aluminum offers a cost-effective, versatile, and sustainable alternative, reducing mold costs and development cycles. This adaptability allows for rapid customization and scalability, meeting diverse market demands and reducing initial investment barriers for businesses.

Enhancing Shower Aesthetics with Surface Treatments

Surface treatments such as anodizing and various mechanical finishes (mirror polishing, brushing, sandblasting) enrich the aesthetic and functional quality of aluminum shower components. Anodizing, in particular, offers a durable, friction-reducing finish available in a wide range of colors, while mechanical finishes provide designers with creative freedom to achieve different visual effects.

Future Directions and Advantages of Aluminum in Showers

Looking ahead, aluminum profiles hold promise for smart shower systems, leveraging their electrical conductivity and anodized insulation properties for integrated electronic functionalities. Furthermore, the aluminum extrusion industry’s rapid development points towards more sustainable manufacturing practices, with a push towards hydropower and reduced reliance on coal.

Conclusion

Aluminum profiles are set to redefine the landscape of shower design and manufacturing. With benefits spanning design flexibility, cost-effectiveness, and environmental sustainability, aluminum emerges as a superior choice for modern bathroom fixtures. As technology and sustainability continue to drive industry trends, aluminum’s role in shower industrial design is not just promising—it’s essential for the future.

This exploration into the benefits and future potential of aluminum in shower design underscores its pivotal role in elevating both the form and function of modern bathroom fixtures.