Introduction

Aluminum profile radiators have become a cornerstone in various industries, including automobiles, electronic equipment, and lighting. These radiators play a crucial role in ensuring efficient heat dissipation, which is vital for the optimal performance and longevity of equipment.

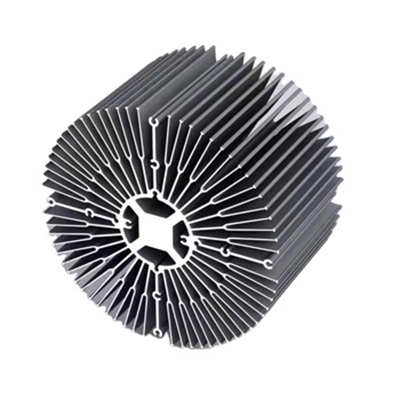

Aluminum Profile Radiator Shells

At the heart of aluminum profile radiators is the radiator shell, a critical component designed to protect internal heat dissipation elements and enhance the overall structure of the radiator. The shell ensures that the radiator functions effectively while maintaining its durability and stability.

Manufacturing Process of Aluminum Profile Radiator Shells

Aluminum profiles are the preferred material for radiator shells due to their lightweight, corrosion-resistant, and easy-to-maintain properties. The manufacturing process involves several advanced technologies such as stamping, hot pressing, processing, and spraying, which together ensure the production of high-quality radiator shells.

Design Considerations for Aluminum Profile Radiator Shells

Designing an effective aluminum profile radiator shell requires careful consideration of several factors:

Shell Size: The dimensions must accommodate the specific requirements of the application.

Heat Dissipation Power: Ensuring sufficient power to manage heat effectively.

Fan Configuration: Integrating fans appropriately to enhance cooling efficiency.

Installation Method: Simplifying installation to improve usability and maintenance.

These considerations help create a radiator that is efficient, safe, and reliable.

Advantages of Aluminum Alloy Radiators

Aluminum alloy radiators offer several benefits:

Lightweight: Aluminum alloy radiators are significantly lighter than traditional copper radiators, reducing the overall weight of mechanical systems and improving fuel efficiency in automotive applications.

Corrosion Resistance: The excellent oxidation and corrosion resistance of aluminum alloys ensure longevity and reduced maintenance over time.

Simple Manufacturing Process: The relatively simple and cost-effective manufacturing process allows for large-scale production, making aluminum alloy radiators more affordable.

Applications of Aluminum Profile Radiators

Automobiles: In the automotive industry, aluminum profile radiators help manage engine temperatures, enhancing performance and fuel efficiency.

Electronic Equipment: In electronics, efficient heat dissipation is crucial to prevent overheating and maintain device functionality. Aluminum profile radiators are integral in cooling systems for computers and other electronic devices.

Lighting Equipment: High-performance lighting systems, especially those with LED technology, require effective heat management. Aluminum profile radiators help maintain optimal temperatures, ensuring the longevity and reliability of lighting fixtures.

Conclusion

Aluminum profile radiators are indispensable across various industries due to their superior heat dissipation capabilities, lightweight, and durability. As technology advances, we can expect further innovations in the design and application of these radiators, driving efficiency and performance in even more sectors.