Aluminum Profile CNC Machining vs. Ordinary CNC Machining

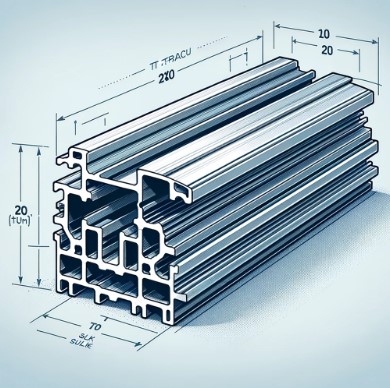

The first thing to note is that aluminum profiles present specific challenges due to their slender nature. To accommodate these characteristics, CNC machining centers for aluminum profiles are designed with narrow and long worktables. These tables typically do not exceed a width of 5000mm and have lengths ranging from 6500mm to 7000mm, making them ideal for processing the typical 6m aluminum profiles. Moreover, while the maximum spindle speed of a general machining center might hover below 80,000 RPM, the speed for aluminum machining can reach or even exceed 18,000 RPM, reflecting the need for precision and efficiency in aluminum processing.

Characteristics of Aluminum Profile CNC Machining

Machining aluminum profiles involves several unique processes not commonly used with other materials. These include milling grooves, drilling, and tapping, whereas milling planes/surfaces and drilling are less frequently employed. The adaptation to these processes is not just about the machining operation itself but also about selecting the right tools and parameters to match the material’s properties.

Applications and Impacts

Aluminum profile CNC machining finds its applications across various fields, from industrial machinery to architectural structures. The precision and adaptability of CNC machining allow for the creation of complex and durable components, enhancing the functionality and aesthetic appeal of aluminum products.

Optimization Strategies for Aluminum Profile CNC Machining

Achieving optimal results in aluminum profile CNC machining involves choosing the right machining center and tools, tailored to the material’s characteristics. Adjustments in machining parameters, such as speed, feed rate, and cooling, are crucial to accommodate the thermal conductivity and softness of aluminum.

Conclusion

The unique world of aluminum profile CNC machining showcases the intersection of technology and material science. As we continue to push the boundaries of what’s possible with aluminum, understanding and optimizing these machining processes become increasingly important. With the right approach, the precision and efficiency of CNC machining can unlock the full potential of aluminum profiles, paving the way for innovations in design and functionality.

This exploration into aluminum profile CNC machining not only highlights the technical differences and challenges but also underscores the importance of this process in modern manufacturing. As the demand for lightweight and high-strength materials like aluminum grows, so does the need for specialized machining techniques that ensure precision, efficiency, and quality in every cut.