In the realm of industrial manufacturing and design, a silent revolution is taking place, centered around a material known for its strength, flexibility, and sustainability: aluminum. Industrial aluminum profiles, with their capacity for rapid customization and application across a vast spectrum of industries, have quickly become a cornerstone of modern industrial innovation. This blog post explores the multifaceted advantages and applications of industrial aluminum profiles, shedding light on why they are increasingly preferred in automation, robotics, mechanical equipment, and even automobile manufacturing.

Why Industrial Aluminum Profiles?

The question at the heart of this exploration is straightforward: What makes industrial aluminum profiles so indispensable to contemporary manufacturing? The answer lies in their unique blend of versatility, customization, and sustainability.

Comprehensive Range and Specifications

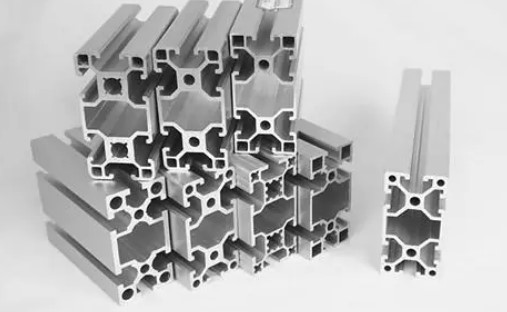

Industrial aluminum profiles come in an array of types and specifications, complemented by a wide range of accessories. This variety allows for the design and creation of custom frame structures tailored to specific needs—be it workbenches, conveyor line brackets, or protective equipment covers—highlighting the material’s adaptability and capacity to meet diverse structural requirements.

Versatility and Environmental Benefits

One of the most compelling features of industrial aluminum profiles is their unparalleled versatility. They can be reused and recycled, promoting environmental sustainability. The ease of assembly and disassembly, coupled with a modular installation approach, not only shortens construction periods but also extends the lifecycle of the structures they form.

No-Weld, Easy-Adjustment Design

The innovative no-weld design of industrial aluminum profiles simplifies adjustments and modifications. Frames can be easily assembled, disassembled, and reconfigured without the need for welding, offering flexibility and adaptability in dynamic industrial environments.

Precision Engineering and Aesthetic Appeal

Industrial aluminum profiles are manufactured with strict adherence to dimensional tolerances and high surface finish requirements. The anodizing process not only enhances corrosion resistance but also adds to the aesthetic appeal of the profiles, making them a preferred choice for visible structures in high-tech environments.

Efficiency in Assembly and Productivity

The simplicity and speed of assembly inherent to industrial aluminum profiles translate directly into increased productivity. The fact that their processing is unaffected by environmental conditions means that assembly can proceed smoothly and efficiently, free from the constraints of time and place.

Applications in Various Industries

The applications of industrial aluminum profiles are as diverse as they are innovative. From the assembly lines of the automotive industry to the precision equipment of university laboratories, these profiles provide a foundation for structures that demand strength, precision, and aesthetic appeal.

Conclusion

Industrial aluminum profiles stand at the intersection of innovation, efficiency, and sustainability. Their widespread adoption across industries underscores their significant role in modern manufacturing, offering a testament to the strategic advantage they provide. As industries continue to evolve, the versatility and efficiency of industrial aluminum profiles will undoubtedly play a pivotal role in shaping the future of industrial design and manufacturing.