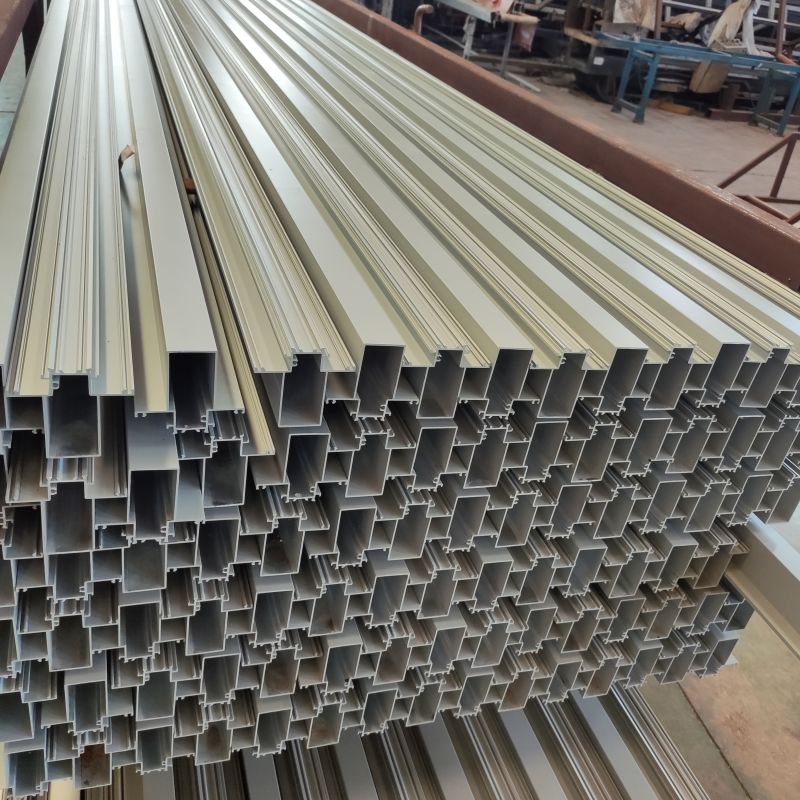

In today’s rapidly advancing industrial landscape, the demand for assembly line aluminum profile frames is surging. These frames serve as integral components in a wide array of applications, ranging from automation equipment to industrial fences. However, with the proliferation of manufacturers in the market, choosing the right supplier is paramount to avoid potential safety hazards and ensure optimal performance.

Advantages of Assembly Line Aluminum Profile Frames

Lightweight and Medium Hardness: Unlike traditional steel tube frames, aluminum profiles boast a remarkable combination of lightweight construction and medium hardness. With one-third the specific gravity of steel, aluminum profiles offer a viable solution for applications where stringent load-bearing requirements are not essential.

Ease of Installation: The installation process of assembly line aluminum profile frames is remarkably straightforward. Utilizing right-angle connectors, these frames can be easily assembled without the need for welding or painting, streamlining the manufacturing process and reducing costs significantly.

Minimal Tolerance and Deformation: One of the key advantages of aluminum profiles lies in their minimal tolerance and deformation. Unlike steel tube frames, which can undergo linear deformation under high temperatures, aluminum profiles maintain their structural integrity, ensuring consistent performance and longevity.

Flexibility in Size Adjustment: Another notable feature of assembly line aluminum profile frames is their flexibility in size adjustment. During installation and debugging processes, these frames can be easily resized to accommodate changing requirements—a level of adaptability that traditional steel pipes simply cannot match.

Oxidation Resistance and Corrosion Prevention: Aluminum profiles exhibit excellent oxidation resistance, safeguarding against corrosion and ensuring prolonged durability. In contrast, steel pipes are susceptible to corrosion, which not only compromises the appearance but also undermines the functionality of equipment over time.

Applications of Assembly Line Aluminum Profile Frames

From their inception as frame parts for assembly line equipment to their evolution into versatile components for automation equipment, workbenches, and industrial fences, assembly line aluminum profile frames have revolutionized various industrial sectors. Their adaptability and reliability make them indispensable assets in modern manufacturing environments, where efficiency and safety are paramount.

Conclusion

In conclusion, the advantages of assembly line aluminum profile frames are undeniable. From their lightweight construction to their corrosion-resistant properties, these frames offer a superior alternative to traditional steel tube frames. As industries continue to evolve, embracing innovation in frame design becomes increasingly crucial. By opting for assembly line aluminum profile frames, manufacturers can enhance efficiency, mitigate risks, and propel their operations into the future. Choose quality, choose safety—choose assembly line aluminum profile frames.