Introduction

Aluminum processing is a crucial aspect of modern manufacturing, playing a significant role across various industries. By transforming raw aluminum into usable products through techniques like casting, extrusion, and surface treatment, aluminum processing provides essential materials for everything from industrial machinery to architectural marvels. This guide delves into the methods and benefits of aluminum processing, offering insights into its extensive applications.

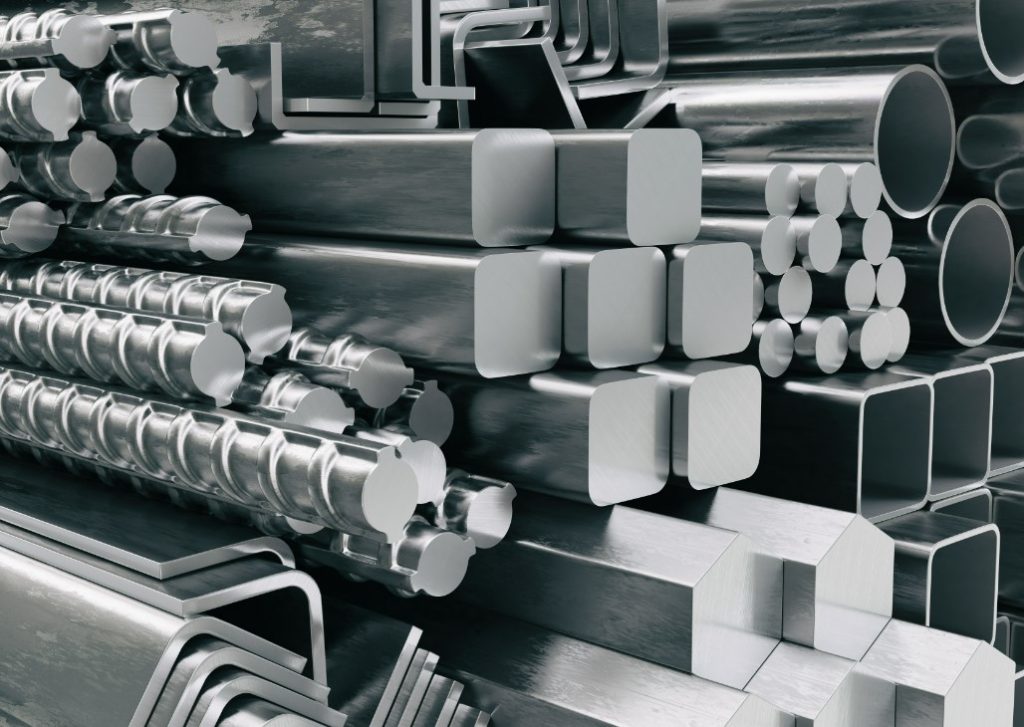

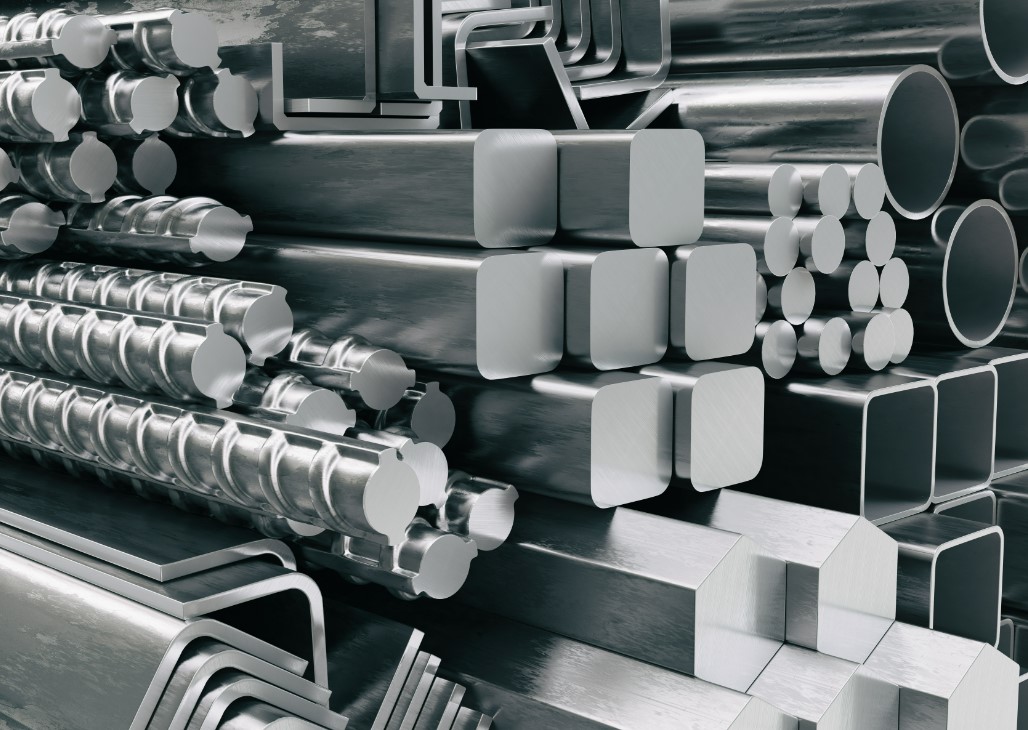

Types of Aluminum Processing

Deformation Processing

Deformation processing of aluminum includes two primary techniques: extrusion and calendering. These methods shape aluminum into various products:

Extrusion Technology: This process involves forcing aluminum through a die to create extruded profiles. These profiles are categorized into industrial aluminum profiles and architectural aluminum profiles. Industrial profiles are used in machinery and equipment, while architectural profiles are utilized in building structures.

Calendering Technology: Also known as rolling, this process produces aluminum plates, belts, and foils. These materials are essential in packaging, construction, and electronics due to their malleability and strength.

Casting Processing

Casting processing involves melting aluminum and pouring it into molds to create precision aluminum alloy die castings and precision sheet metal. This method is integral to producing complex shapes and components required in automotive, aerospace, and consumer electronics industries.

Aluminum Profile Processing

Extrusion Process

Aluminum profile processing starts with the extrusion of aluminum cast rods through molds using an extruder. This initial shaping is followed by several critical steps:

- Artificial Aging: This heat treatment enhances the strength and durability of the extruded profiles.

- Surface Treatment: Various treatments like anodizing, powder coating, and painting are applied to improve corrosion resistance and aesthetic appeal.

- Deep Processing: Includes cutting, drilling, and other finishing operations to meet specific application requirements.

Surface Treatment Techniques

Surface treatments are vital for enhancing the appearance and performance of aluminum profiles:

- Anodizing Process: This electrochemical process increases the thickness of the natural oxide layer on the surface of aluminum. Techniques include alkaline sand and acid sand processes, both of which create a matte effect by corroding the surface. While these treatments provide a natural look, they can be environmentally unfriendly and potentially damage the aluminum profile.

- Sandblasting: Unlike chemical processes, sandblasting maintains a bright inner cavity, making it a preferred choice for specific applications requiring a clean finish.

Applications and Benefits

Industrial Applications

Aluminum’s properties make it indispensable in various industries:

- Manufacturing: Used in machinery, tools, and equipment for its lightweight and strength.

- Construction: Employed in structural components, frames, and supports due to its durability and corrosion resistance.

- Automotive: Essential for vehicle parts, reducing weight and improving fuel efficiency.

Architectural Applications

In architecture, aluminum profiles are prized for their versatility and aesthetic qualities:

- Building Facades: Provide sleek, modern looks and weather resistance.

- Windows and Doors: Offer customization in finishes and colors, enhancing building design while ensuring durability.

Conclusion

Aluminum processing is a cornerstone of modern industry, offering a versatile and sustainable material solution. From the initial casting to the final surface treatment, aluminum products are integral to many applications, providing unmatched benefits in terms of strength, weight, and aesthetics. Whether in industrial or architectural contexts, aluminum continues to prove its value. Explore the world of aluminum processing and discover how this remarkable material can meet your needs.