Introduction

Mirror aluminum plates, known for their stunning reflective surfaces, are a popular choice in various industries for their aesthetic appeal and practicality. In this guide, we delve into the intricacies of mirror aluminum plates, exploring their processing techniques, different types, and wide-ranging applications.

Mirror Aluminum Plate Processing

Mirror aluminum plates undergo meticulous processing methods, primarily mechanical in nature. These include material removal processing involving grinding, polishing, and buffing, as well as non-cutting processing such as rolling and extrusion. Each method requires specific equipment and expertise, ensuring the desired mirror effect is achieved.

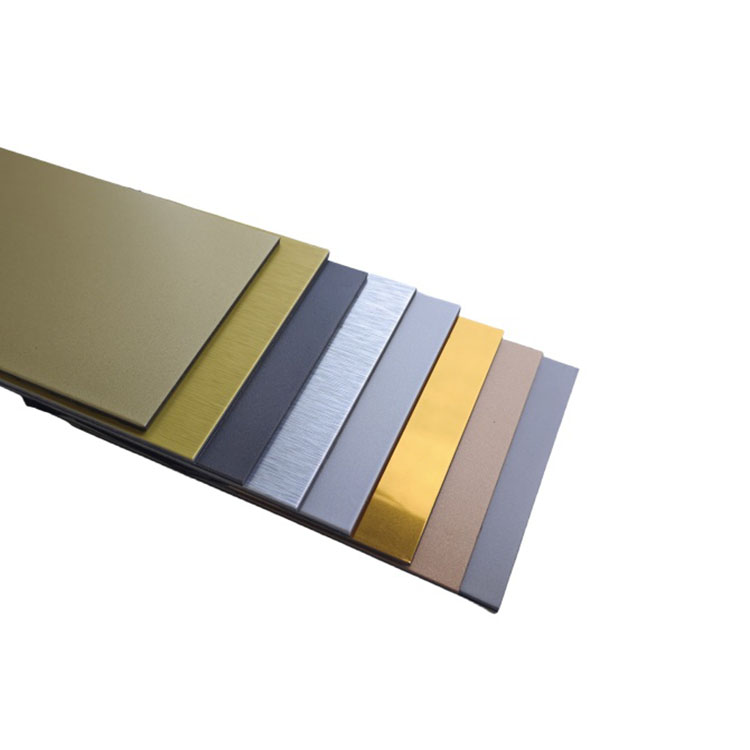

Types of Mirror Aluminum Plates

The market offers various types of mirror aluminum plates, including filmed, polished, oxidized, and super mirror plates. Each type has its unique characteristics, catering to different consumer preferences and needs. Understanding the differences between these types is crucial for making informed decisions.

Choosing the Right Mirror Aluminum Plate

When selecting a mirror aluminum plate, precision and durability are paramount. Imported plates from Germany and Italy undergo surface protection treatments, ensuring stable mirror reflectivity over time. Japanese plates offer a distinctive grained effect but may have higher loss rates. Consumers are advised to choose based on their specific requirements.

Applications of Mirror Aluminum Plate

Thanks to its excellent anti-corrosion properties, mirror aluminum plates find extensive use in the construction industry, particularly for indoor and outdoor decoration. They are also favored in electronic products, household appliances, and luggage manufacturing, owing to their durability and aesthetic appeal.

Conclusion

Mirror aluminum plates continue to shine bright in various industries, offering both beauty and functionality. As technology advances, we can expect further innovations in processing techniques and applications, cementing their position as a highly versatile material in the modern world.