Follow in the footsteps of Rina, take you to know more aluminum profile products

Hey there, aluminum enthusiasts! Rina Meng here, your trusty guide to the captivating world of aluminum profiles. Today, we’re diving headfirst into the realm of extruded heat sinks and exploring their secret hideouts. Get ready for a wild ride filled with cool facts and a sprinkle of humor!

Picture this: you’re basking in the warm glow of a commercial LED light. Ever wondered how those tiny light sources stay so cool? Well, my friends, it’s all thanks to our hero, the extruded heat sink! These bad boys provide effective cooling for LED lights, making sure they shine bright without breaking a sweat. It’s like having a personal air conditioner for your illuminating buddies! And guess what? These heat sinks can be mass-produced, so they’re popping up everywhere, lighting up our lives in more ways than one.

But wait, there’s more! Let’s shift our focus to the world of circuit boards and PCBs. These electronic wonders power our gadgets and gizmos, but they can get pretty toasty. That’s where our trusty aluminum heat sink extrusions come to the rescue! With their precise combination of vertical and horizontal cooling, they ensure that our circuit boards stay chill and avoid overheating. It’s like giving your electronic companions a refreshing breeze on a scorching summer day. Plus, these heat sinks come in various thicknesses and customized forms, making them the superheroes of thermal management. Talk about versatility!

Now, let’s take a detour to the land of electronic instruments and equipment. You know those devices that make our lives easier and more entertaining? Well, they generate heat too, and that’s where our heat sinks step in. These indispensable devices effectively dissipate the heat generated by output transistors, ensuring that our electronic buddies don’t break a sweat. It’s like having a personal fan for your favorite gadgets, keeping them cool and running smoothly. How cool is that?

But wait, there’s more! Buckle up for a ride to the automotive world. In the realm of automotive electronic equipment, heat sinks play a crucial role in maintaining stable temperatures for high-density components. Whether it’s a traditional automobile or a futuristic New Energy Vehicle (NEV), these heat sinks work tirelessly to keep things cool under the hood. It’s like having a superhero cape that protects your car’s electronic brain from the scorching heat of the road. Talk about automotive awesomeness!

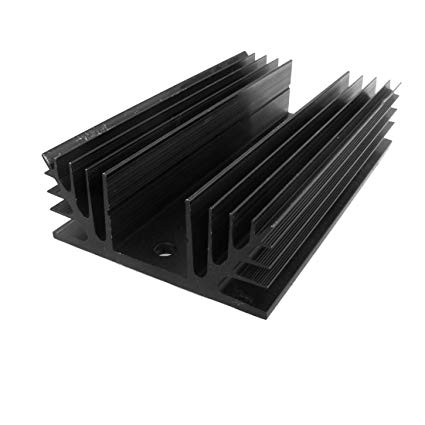

Now that we’ve explored the secret hideouts of extruded heat sinks, let’s talk about their purpose. These heat sinks are specifically designed to extract heat from electronic components, ensuring that they stay within their temperature comfort zone. It’s like having a personal cooling system for your gadgets, preventing them from getting all hot and bothered. And to top it off, these heat sinks are often polished, and some even get fancy makeovers with anodization or powder coating. It’s like giving your heat sink a stylish outfit while providing surface protection and corrosion resistance. Who said heat sinks can’t be fashionable?

Overall, my aluminum aficionados, extruded heat sinks are the unsung heroes of the electronic world. They keep our LED lights cool, our circuit boards in check, our electronic devices happy, and our cars running smoothly. From commercial lighting to electronic instruments and beyond, these heat sinks work their magic in various domains, ensuring that our technology stays cool and collected.

Thank you for joining me on this adventure into the world of extruded heat sinks. I hope you’ve gained some valuable insights and had a few chuckles along the way. Remember, when it comes to cooling technology, there’s no problem too hot to handle!

Until next time, stay cool and keep shining bright!