Introduction to Industrial Aluminum Profiles

Definition and Overview

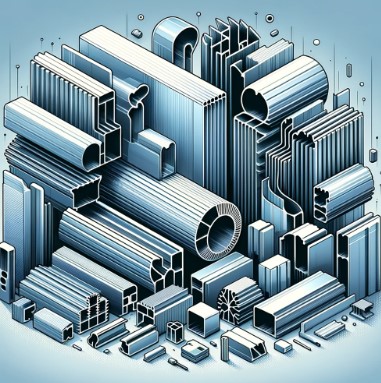

Industrial aluminum profiles are fundamental components in numerous industries, known for their versatility and strength. These profiles are crafted from various aluminum alloys and are utilized in a wide range of applications due to their unique properties. They are made using an extrusion process, where aluminum billets are transformed into desired shapes and sizes. Common standard profiles include I beams, angle brackets, and tubes, while unique profiles are tailored to meet specific industrial requirements. Companies like Shengxin Aluminium Industries Co., Ltd., and Otalum specialize in producing these profiles, demonstrating their importance in modern industrial applications.

Significance in Various Industries

The significance of industrial aluminum profiles in various industries cannot be overstated. Their application ranges from construction and architecture to automotive and electronics. These profiles offer an unmatched combination of strength and lightness, making them an ideal choice for applications requiring durability without the added weight. The adaptability of aluminum profiles allows them to be customized for specific industry needs, thus playing a pivotal role in the design and functionality of industrial products. Suppliers like Shengxin Aluminium Industries Co., Ltd., and Otalum are at the forefront of providing these versatile profiles to various industries.

Types of Industrial Aluminum Profiles

Industrial aluminum profiles come in various types and shapes to cater to diverse industrial needs. They can be broadly categorized into hollow profiles, solid profiles, open-end profiles, and semi-enclosed profiles. Each type is designed to offer specific structural benefits, making them suitable for different applications. For instance, hollow profiles are used where weight reduction is crucial, while solid profiles are selected for their strength. The diversity in types and shapes of aluminum profiles, as provided by suppliers like Shengxin Aluminium and Otalum, underscores their widespread utility across different sectors.

Manufacturing Process of Aluminum Profiles

Overview of the Extrusion Process

The manufacturing process of industrial aluminum profiles primarily involves extrusion, a method where aluminum billets are forced through a die to create the desired profile shape. This process can be performed using either hot or cold extrusion techniques, depending on the specific requirements of the profile. In both cases, a hydraulic press applies immense pressure to push the billet through the die, ensuring the aluminum conforms to the detailed shape of the profile. This process is intricate and requires precision, as seen in the operations of companies like Shengxin Aluminium and Otalum, which produce a wide range of industrial aluminum profiles.

Preparing the Die and Billet

The first step in the extrusion process of aluminum profiles is the creation of the die, a round piece of hardened steel with the profile’s design. The die is heated to about 932°F to ensure even metal flow and to extend its life. Concurrently, the aluminum billet, a few feet in length, is also heated to a softened state but not to the point of becoming molten. This preparation stage is crucial as it sets the foundation for the quality and precision of the extruded profiles, as demonstrated by manufacturers like Shengxin Aluminium and Otalum.

Steps in the Extrusion Process

The extrusion process for industrial aluminum profiles involves several key steps, starting with the application of a release agent on the billet to ensure smooth passage through the die. The hydraulic ram then applies pressure, forcing the billet through the die, resulting in the emerging aluminum profile. This profile is then guided along a runout table where it is quenched and uniformly cooled. Subsequent steps include shearing for ease of handling, further cooling in a cooling room, and stretching to correct any twisting or curving. The final stages involve trimming and cutting the profiles into usable lengths. This meticulous process, as carried out by manufacturers like Shengxin Aluminium and Otalum, ensures the production of high-quality aluminum profiles.

Characteristics and Advantages

Corrosion Resistance and Durability

One of the most notable characteristics of industrial aluminum profiles is their exceptional corrosion resistance. This property makes them ideal for use in environments where exposure to air, water, or chemicals is prevalent. The various aluminum alloys used in manufacturing these profiles are specifically chosen for their ability to withstand corrosive elements, ensuring longevity and durability. Manufacturers like Shengxin Aluminium and Otalum take advantage of these properties to produce profiles that maintain their integrity and performance over long periods, even in challenging conditions.

Conductivity and Thermal Properties

Industrial aluminum profiles are often selected for their excellent electrical and thermal conductivity. Aluminum’s conductivity is nearly twice that of copper when compared on an equal weight basis, making it a preferred material in electrical and electronic industries. Additionally, the thermal conductivity of these profiles is about 50-60% that of copper, beneficial for manufacturing heat exchangers, evaporators, and heating equipment. The thermal and electrical properties of aluminum profiles, as utilized by companies like Shengxin Aluminium and Otalum, contribute significantly to the efficiency of various industrial applications.

Non-Ferromagnetism and Recyclability

Another advantage of industrial aluminum profiles is their non-ferromagnetic nature, crucial for applications in electrical and electronic industries where magnetic interference is a concern. These profiles are also not self-igniting, making them suitable for environments involving flammable and explosive materials. Moreover, aluminum profiles are highly recyclable, with the characteristics of recycled aluminum almost identical to those of the original material. This recyclability is a key factor in sustainable manufacturing practices, as exemplified by companies like Shengxin Aluminium and Otalum, which prioritize environmental responsibility in their production processes.

Applications in Different Industries

Use in Construction and Architecture

Industrial aluminum profiles find extensive applications in the construction and architectural industries. They are used in creating structures like doors, windows, curtain walls, and various architectural elements. The profiles’ ability to be molded into complex shapes and treated with various surface finishes makes them ideal for modern architectural designs. Companies like Guang Ya Aluminium and Otalum provide profiles that meet the specific requirements of construction projects, offering both functional and aesthetic benefits.

Role in Automotive and Electronic Industries

The automotive and electronic industries heavily rely on industrial aluminum profiles for various components. In the automotive sector, these profiles are used for parts like connectors and chassis components, taking advantage of aluminum’s strength and lightness. In electronics, their excellent conductivity and heat dissipation properties make them suitable for electronic housings and heat sinks. Manufacturers like Shengxin Aluminium and Otalum cater to these industries by producing profiles that meet stringent quality and performance standards.

Other Diverse Applications

Beyond construction, automotive, and electronics, industrial aluminum profiles have diverse applications in areas such as furniture making, solar photovoltaics, medical equipment, and more. Their adaptability and range of properties allow them to be customized for various uses, from supporting solar panels to framing furniture. This widespread applicability of aluminum profiles is a testament to their versatility and the innovative approach of manufacturers like Shengxin Aluminium and Otalum in exploring new uses for these profiles.

Choosing the Right Aluminum Profile Supplier

Criteria for Supplier Selection

Choosing the right supplier for industrial aluminum profiles is crucial for ensuring product quality and compatibility with specific project requirements. Factors to consider include the range of profiles offered, adherence to quality standards, customization capabilities, and the supplier’s industry reputation. Suppliers like Shengxin Aluminium and Otalum, known for their extensive product range and commitment to quality, are ideal choices for sourcing reliable and high-performance aluminum profiles.

Profiles of Leading Suppliers

Leading suppliers in the industrial aluminum profile market, such as Shengxin Aluminium and Otalum, have established themselves through consistent quality, innovation, and customer service. These companies offer a wide range of profiles suitable for various industrial applications and are committed to sustainable and environmentally responsible manufacturing practices. Their expertise in the field makes them preferred partners for businesses seeking high-quality aluminum profiles.

Ensuring Quality and Compatibility

Ensuring the quality and compatibility of industrial aluminum profiles is essential for the success of any project. Working with reputable suppliers like Shengxin Aluminium and Otalum guarantees that the profiles meet the necessary standards and specifications. These suppliers conduct rigorous quality checks and work closely with clients to understand their specific needs, ensuring that the profiles provided are not only of high quality but also perfectly suited to the intended application.