Follow Rina to show you more information about aluminum profiles

Extruded aluminum profiles and die-cast aluminum alloy products are two different aluminum processing technology products, and there are big differences between them. The following are the differences, advantages and disadvantages between the two:

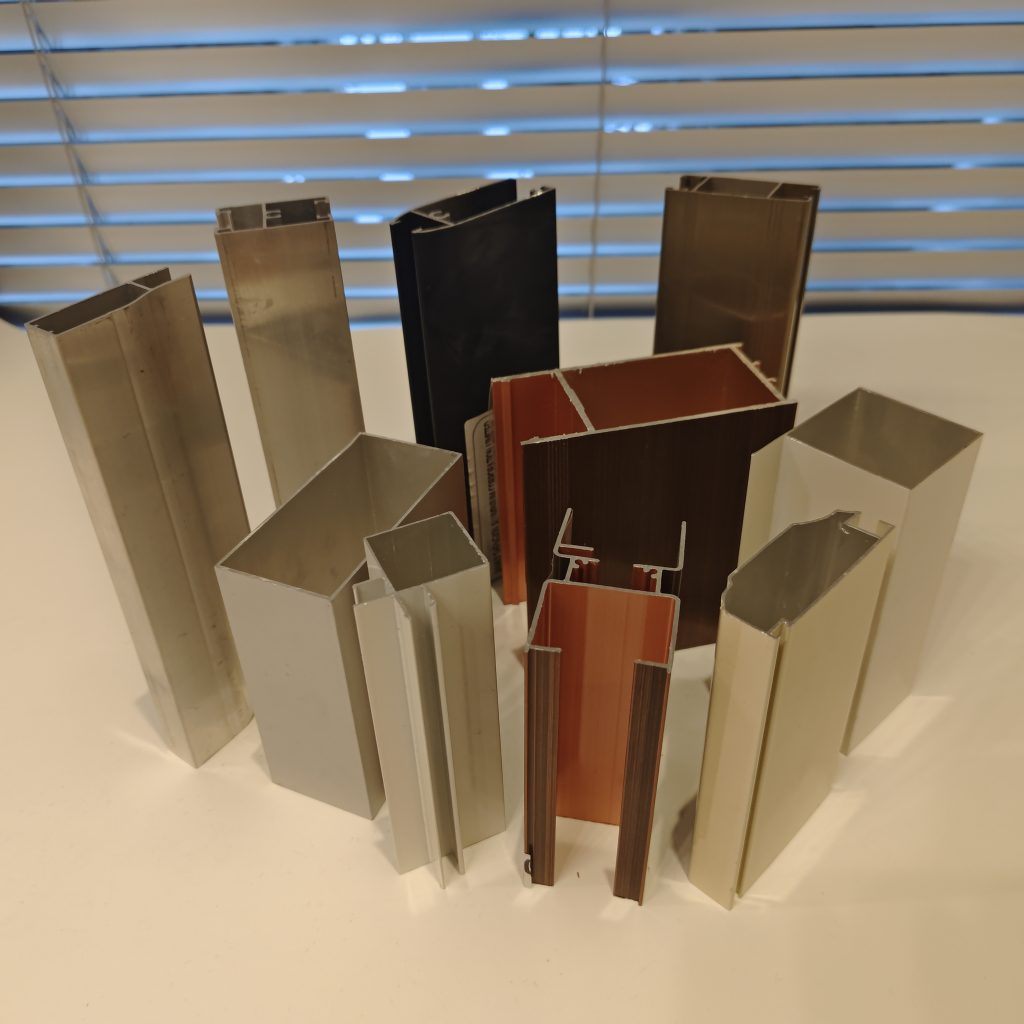

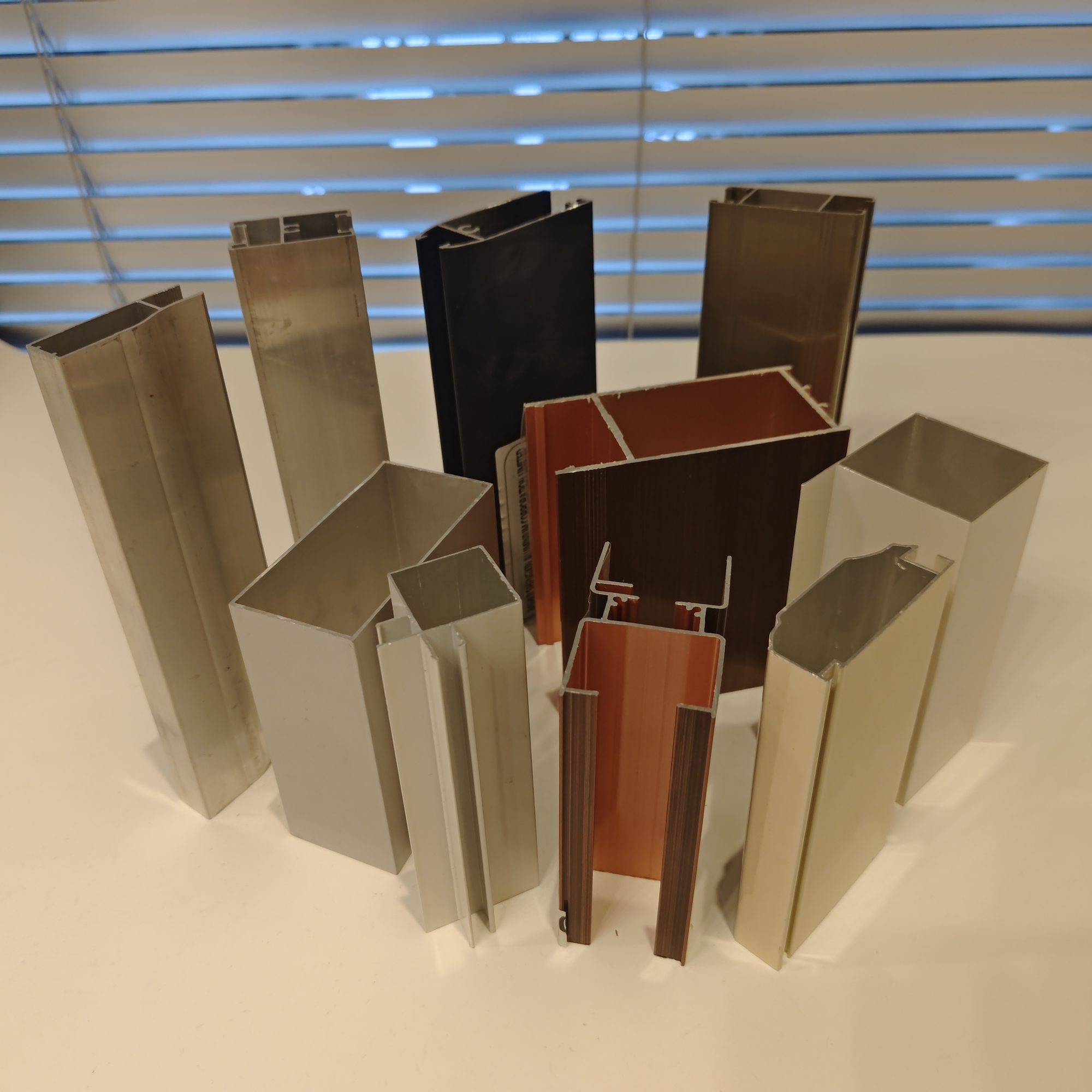

- Extruded aluminum profiles

Extruded aluminum profiles are made by heating aluminum rods or aluminum ingots to a certain temperature and then extruding them out of the die orifices using an extruder to form aluminum materials with the required cross-sectional shape.

advantage:

a) Light weight, the density is only 1/3 of other metal materials, suitable for lightweight design.

b) Good plasticity, adaptable to various complex profile sections.

c) Good corrosion resistance, can be widely used in construction, automobile, aviation and other industries.

d) Various surface treatments, such as anodizing, electrophoresis, spraying, etc., can achieve decorative effects of various colors and textures.

shortcoming:

a) Internal stress is easily generated during the production process, leading to profile deformation.

b) The tensile strength is low at high temperatures and the high temperature resistance is limited. - Die-cast aluminum alloy products

Die-cast aluminum alloy products are made by injecting molten aluminum alloy into a steel mold, rapidly solidifying it under high pressure, and then removing the product from the mold.

advantage:

a) Suitable for large-scale production and high production efficiency.

b) Parts with higher precision and good surface finish can be manufactured.

c) Die-cast products have good dimensional stability and mechanical properties.

d) Aluminum alloy products with complex shapes and thin walls can be manufactured.

shortcoming:

a) There are holes with relatively large amounts of gas and relatively low strength.

b) The surface treatment process is relatively complex, such as deburring, chamfering, polishing, etc.

c) The mold cost is high and not suitable for small batch production.

Summary: Extruded aluminum profiles and die-cast aluminum alloy products each have their own advantages and disadvantages. Extruded aluminum profiles are more suitable for making products with complex cross-sections and undemanding strength requirements, while die-cast aluminum alloy products are suitable for mass production, high precision, smooth surfaces, and complex shapes. Appropriate processing technology should be selected based on product requirements and actual application scenarios.