In contemporary construction, aluminum alloy doors and windows are becoming increasingly popular due to their exceptional properties and benefits. This article delves into the various characteristics that make aluminum alloy doors and windows a preferred choice for modern buildings.

Lightweight and High Strength

Aluminum alloy materials are known for their low density and high strength. The door and window frames and leaf profiles are designed as hollow thin-walled composite sections. This design not only makes the profiles lighter but also enhances their cross-sectional strength. The lightweight nature of these profiles makes them easier to handle and install, without compromising on strength and durability.

Good Sealing Performance

One of the standout features of aluminum alloy profiles is their excellent sealing performance. The material can be easily formed into complex cross-sectional structures through extrusion molding processes. This capability allows for the production of profiles that meet stringent requirements for hardware assembly, sealing, thermal insulation, and sound insulation. As a result, aluminum alloy doors and windows offer superior airtightness, watertightness, thermal insulation, and sound insulation compared to other materials.

High Product Precision

Aluminum alloy profiles boast high rigidity, which is further enhanced by the cold connection production process. Unlike steel doors and windows, which rely on welding, aluminum alloy components are connected using screws, bolts, rivets, or angle codes. This method avoids the deformation often caused by uneven heating during welding, ensuring higher production accuracy and consistency.

Beautiful Facade

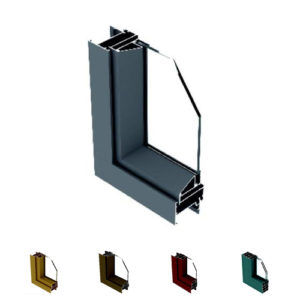

Aesthetically, aluminum alloy doors and windows provide a sleek and modern appearance. They can be manufactured in large sizes and grids, creating a simple and bright building facade. The advanced surface treatment processes allow for a variety of colors and finishes, significantly enhancing the decorative appeal of these doors and windows. This versatility makes them a favorite in both residential and commercial architecture.

Good Weather Resistance

Aluminum alloy door and window profiles undergo various surface treatments such as oxidation, electrophoresis, powder spraying, and painting. These treatments confer excellent weather resistance, ensuring that the profiles do not fade, shed, or corrode over time. The durability and low maintenance requirements of aluminum alloy doors and windows make them a practical choice for long-term use in diverse climatic conditions.

High Cost Performance

In terms of cost performance, aluminum alloy doors and windows excel, especially in high-rise buildings and high-end decoration projects. They offer a superior balance of performance, decorative effect, safety, energy efficiency, and maintenance compared to other types of doors and windows. This makes them a cost-effective option without sacrificing quality or functionality.

Convenient for Industrialized Production

The production of aluminum alloy door and window profiles, along with their supporting parts and seals, can be efficiently mass-produced in factory settings. This industrialized production process facilitates the standardization of design, serialization of products, and generalization of spare parts. Consequently, aluminum alloy doors and windows can be easily commercialized, meeting the demands of large-scale construction projects.

Conclusion

Aluminum alloy doors and windows are transforming modern architecture with their unique combination of strength, precision, aesthetics, and cost-effectiveness. Their superior sealing performance, weather resistance, and ease of industrial production further underscore their value in contemporary construction. As the demand for high-quality, durable, and visually appealing building materials continues to rise, aluminum alloy doors and windows stand out as a premier choice for architects and builders alike.