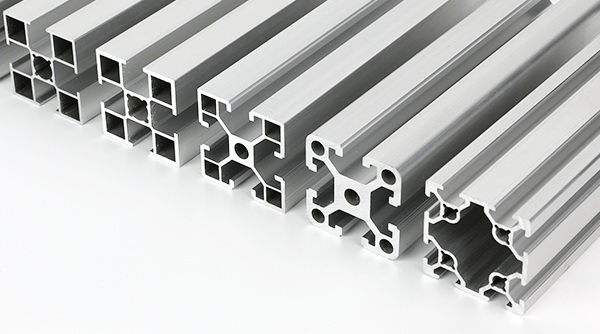

Follow in the footsteps of Rina, take you to know more aluminum profile products

Hey there, aluminum aficionados! Rina Meng here, ready to unravel the mystery behind the varying slot widths of T-slot aluminum profiles. It’s a question that has puzzled many careful friends out there, and today, we’re diving right into it. So buckle up and get ready for a wild ride through the world of T-slot profiles!

The Shape that Sparks Modularity

First things first, let’s talk about the beauty of T-slot profiles. These babies are all about modularity, making assembly and reassembly a breeze. It’s like playing with building blocks, but for grown-ups! You can easily connect and join profiles to create structures that meet your evolving requirements. It’s design flexibility at its finest.

But here’s the kicker—not all T-slot profiles have the same slot width. And you might be wondering, “Why, oh why?” Well, my curious friends, the answer lies in functionality and design. Let’s break it down, shall we?

Design Delights: Size Matters

When it comes to design, the slot width of T-slot profiles can vary. Some profiles have a smaller cross-section with a narrower slot width. And you know what they say—size matters! A smaller slot width means a sleeker appearance from the outside. It’s like wearing a perfectly tailored suit that accentuates all your best features.

Take Hoonly’s 20 series profiles, for example. Their T-slot width is 6.2 mm, with an extra 0.2 mm thrown in for the M6 nut to pass through smoothly. It’s all about those little details, my friends!

Light or Heavy: The Loading Dilemma

Now, let’s talk about the load. When it comes to T-slot profiles, the slot width can determine whether you’re in the light-duty or heavy-duty realm. It’s like choosing between a feather and a dumbbell. Light-duty frameworks typically use profiles with a 6 mm slot width, while heavy-duty frameworks opt for profiles with an 8 mm slot width. It’s all about finding the right fit for the job!

Here’s a fun fact: in China, most fractional 30 series profiles have an 8 mm slot width. But in many other countries, the standard is a 6 mm slot width. Luckily, you can find both specifications at Hoonly. They’ve got you covered, no matter where you’re from!

Choosing the Perfect Fit

Now that we’ve uncovered the secrets behind different slot widths, let’s talk about choosing the right T-slot aluminum profiles for your specific needs. It’s like finding the perfect pair of shoes that not only look good but also provide the right support and comfort. It’s all about functionality, appearance, and strength, my friends.

First things first, consider the expected load. You don’t want your structure collapsing like a house of cards, do you? Calculate the stress caused by material strain and choose the correct size of profiles accordingly. It’s all about finding that sweet spot between strength and durability.

And here’s a pro tip: when installing accessories, be extra careful to avoid profile cracking. You don’t want your masterpiece falling apart, do you? Take your time, follow the instructions, and ensure a secure and sturdy connection.

Overall, my aluminum-loving friends, the varying slot widths of T-slot profiles are all about functionality, design, and load requirements. It’s like a puzzle where each piece has its place. So embrace the diversity, choose wisely, and let your creativity shine through your perfectly chosen profiles.

Thanks for joining me on this aluminum adventure, folks! Remember, when it comes to T-slot profiles, there’s always a slot width that fits just right. Keep exploring, keep innovating, and let your designs reach new heights!

Catch you on the flip side, aluminum enthusiasts! Keep shining bright like the aluminum stars you are!