Introduction

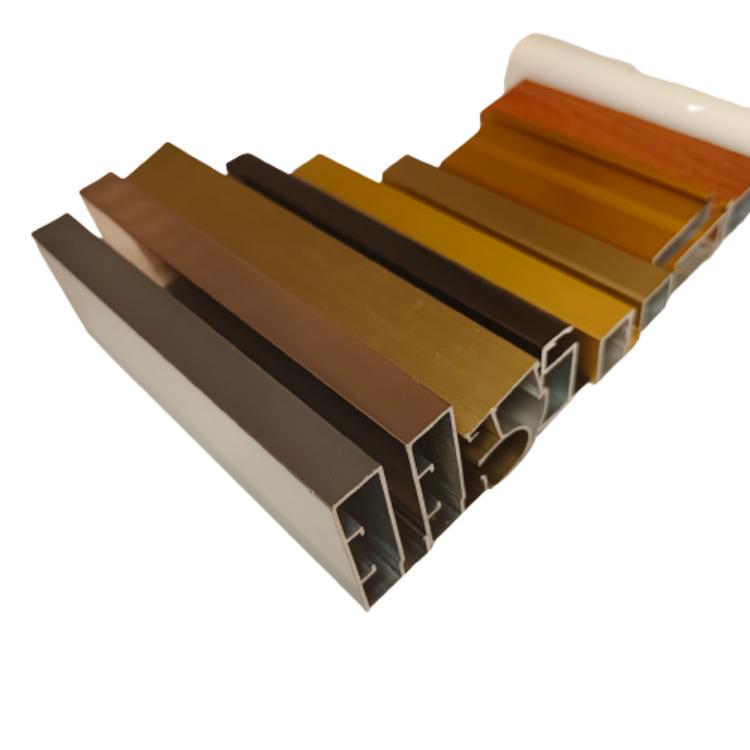

Aluminum, a metal revered for its lightweight and strength, has become a cornerstone in various industries, from construction to automotive. However, its susceptibility to corrosion necessitates the application of surface treatments. This article delves into the myriad of surface treatment processes available for aluminum profiles, highlighting their importance in enhancing both the durability and aesthetics of aluminum products.

Understanding Surface Treatment for Aluminum Profiles

Surface treatment is not just about improving appearance; it’s a vital process for extending the life of aluminum products. The choice of treatment depends on several factors, including the environment of use, expected service life, and economic considerations. This section will explore how these factors play a role in selecting the appropriate treatment method.

Mechanical Treatment Processes

- High-Gloss Cutting: This process involves using an engraving machine to create a high-gloss finish on certain parts of the aluminum, lending a modern and technologically advanced appearance.

- Sandblasting: By bombarding aluminum with high-speed sand, this technique not only cleans the surface but also enhances the metal’s fatigue resistance and improves the adhesion and durability of coatings.

- Brushing: This method involves using sandpaper to create fine lines on aluminum surfaces, resulting in a matte yet lustrous finish that’s both fashionable and functional.

- Polishing: Similar to polishing stainless steel, this process reduces surface roughness, yielding a smoother and more reflective finish.

Chemical Treatment Processes

- Anodizing: This electrochemical process creates a dense oxide layer, significantly increasing the surface hardness and corrosion resistance of aluminum. Hard anodizing is especially crucial in heavy-duty applications like oil cylinders and transmissions.

- Spray Coating: Including both powder and liquid options, electrostatic spray coating is a popular choice in the industry for its durability and finish quality.

- Electroless Plating: Unique for its use of redox reactions without external power, this plating method ensures even coating on complex surfaces.

- Electrophoretic Coating: An advanced technique that deposits organic resin on parts to form a protective layer. The choice between anodic and cathodic electrophoresis depends on the specific application requirements.

Choosing the Right Surface Treatment

Selecting the right surface treatment involves considering durability, cost, aesthetics, and the environment where the aluminum product will be used. This section provides guidance on matching treatment processes with specific applications, ensuring optimal performance and longevity.

Conclusion

The myriad of surface treatment processes available for aluminum profiles not only extend their lifespan but also enhance their aesthetic appeal. Whether it’s for architectural applications or automotive components, the right surface treatment can significantly elevate the performance and appearance of aluminum products.