Introduction

Broken bridge aluminum profiles are a cornerstone in the construction industry, known for their durability and high quality. Despite being among the pricier options, their benefits justify the investment, a point this article will explore in depth.

Properties and Benefits

These aluminum profiles stand out for their remarkable hardness and ability to withstand high stress – up to 180 kilograms per square centimeter. This makes them a top choice in terms of strength and longevity.

Applications in Construction

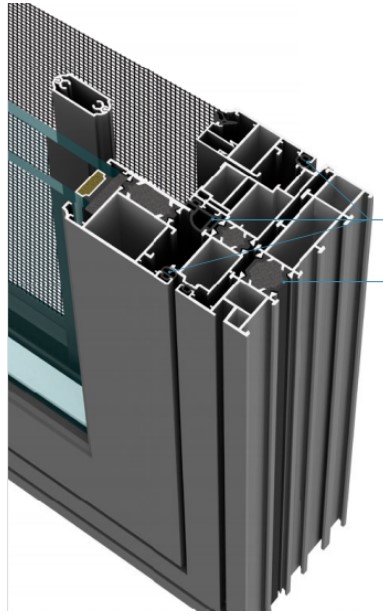

In the construction realm, they are primarily used for doors, windows, and curtain walls. Their impact on building safety and structural integrity is significant, offering a reliable choice for builders and architects.

Critical Role in Aerospace and Shipbuilding

In aerospace, their ability to resist high-pressure environments is crucial, especially for aircrafts that endure extreme altitude conditions. Similarly, in shipbuilding, their anti-rust and waterproof properties are indispensable, particularly in yachts and vessels that demand high-performance materials.

Advanced Design Features

The multi-layer sealing design of these profiles enhances their sealing performance, a key factor in their effectiveness across different industrial applications.

Economic Perspective

While the initial cost may be higher, the long-term benefits and durability of broken bridge aluminum profiles offer a compelling return on investment.

Conclusion

Broken bridge aluminum profiles are a versatile and reliable material in various industries. Their advanced properties and design make them an intelligent choice for projects that demand high-quality materials.