Introduction

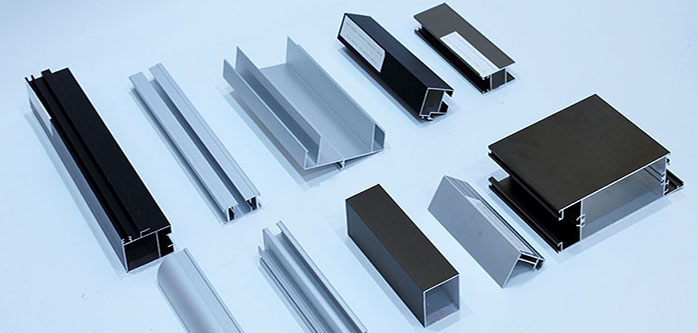

Aluminum profiles are integral to a myriad of industries, from construction and transportation to aerospace and machinery manufacturing. The quality of these profiles is paramount, as it directly affects the performance and longevity of the products they are incorporated into. Understanding the factors that influence the quality of aluminum profiles is crucial for maintaining high standards in manufacturing and application.

Raw Materials: The Foundation of Quality

The starting point of quality aluminum profiles lies in the choice of raw materials. The alloy composition and impurity content play a critical role in determining the physical and chemical properties of the profiles. Different alloy compositions yield varying characteristics in terms of strength, corrosion resistance, and electrical conductivity. Minimizing impurity content and controlling oxide levels during production are vital for enhancing coating performance and corrosion resistance.

Production Process: A Critical Determinant

The production process of aluminum profiles significantly influences their final quality. The processing temperature must be carefully managed; temperatures that are too high can soften the material, reducing its strength and hardness, whereas too low temperatures can make it brittle, compromising its toughness. Pressure control is another pivotal factor. Excessive pressure can lead to material deformation, affecting dimensional accuracy, while insufficient pressure can result in less dense material, diminishing its overall performance. Surface treatments like oxidation, sandblasting, and polishing also play a role, affecting the aluminum profiles’ appearance, corrosion resistance, adhesion, and other properties.

Usage Environment: External Influences

Environmental factors such as humidity, altitude, and ultraviolet radiation exposure also affect the quality of aluminum profiles. High humidity levels can accelerate corrosion and reduce the service life of the profiles, while low humidity can lead to drying out and cracking. In high altitude areas, the reduced air pressure can diminish the density and strength of the aluminum profiles. Prolonged exposure to sunlight leads to surface oxidation and discoloration, impacting both the aesthetic and functional qualities of the aluminum profiles.

Ensuring Quality: Control and Management

Improving the quality of aluminum profiles requires stringent control and effective management throughout the production process. It is imperative to continuously seek technological innovations and research new production methods and technologies. This approach not only enhances the performance and service life of aluminum profiles but also ensures they meet the evolving demands of various industries.

Conclusion

The quality of aluminum profiles is influenced by a combination of factors ranging from raw materials and production processes to environmental conditions. Recognizing and managing these factors is essential for producing high-quality aluminum profiles that meet the rigorous demands of their applications. As the industries that rely on these profiles continue to evolve, so must the processes and technologies used to produce them, ensuring a future where quality and sustainability go hand in hand.