Introduction

- Brief overview of the importance and prevalence of aluminum alloy in manufacturing heat dissipation equipment.

- Explanation of the unique properties of aluminum that make it suitable for this application: lightweight, aesthetically pleasing, high thermal conductivity, and easy to shape.

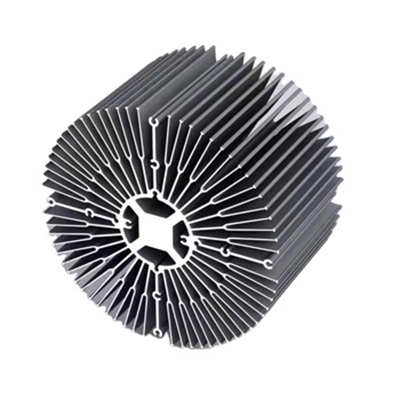

- Introduction to the three main types of aluminum alloy heat sinks and their characteristics.

Section 1: Types and Characteristics of Aluminum Alloy Heat Sinks

- Detailed explanation of the three main types of aluminum alloy heat sinks: flat and wide, comb-shaped or fishbone-shaped; and round or oval outer heat sinks in radial and dendritic shapes.

- Discussion on the size and symmetry of radiator profiles, highlighting the production challenges associated with larger, asymmetrical profiles with deep grooves.

Section 2: The 6063 Aluminum Alloy – A Popular Choice

- Introduction to the 6063 aluminum alloy, explaining its widespread usage in heat sink production.

- Discussion on the properties of 6063 alloy that make it favorable: good extrudability, thermal conductivity, and mechanical properties.

Section 3: Production Process and Quality Control

3.1 Ingot Casting

- Explanation of the importance of starting with a high-quality ingot for successful heat sink production.

- Detailed quality requirements for ingot casting: smooth surface, flat end face, and acceptable cutting slope.

3.2 Mold Design and Material

- Discussion on the critical role of mold design and material in the production of aluminum alloy heat sinks.

- Emphasis on the need for high strength and toughness in each tooth of the mold, and recommendation for using high-quality steel and proper heat treatment methods.

3.3 Reducing Extrusion Force

- Explanation of the relationship between extrusion force and factors such as ingot length, alloy resistance, and ingot state.

- Strategies for reducing extrusion force: optimizing ingot length and considering the use of pure aluminum for trial extrusions.

3.4 Extrusion Process

- Highlighting the significance of the first trial of the extrusion die and recommendations for a successful trial.

- Tips for controlling the extrusion speed and maintaining an appropriate mold temperature throughout production.

Conclusion

- Recap of the key points discussed in the article.

- Emphasis on the importance of quality control and careful process management in the production of aluminum alloy heat sinks.