Introduction

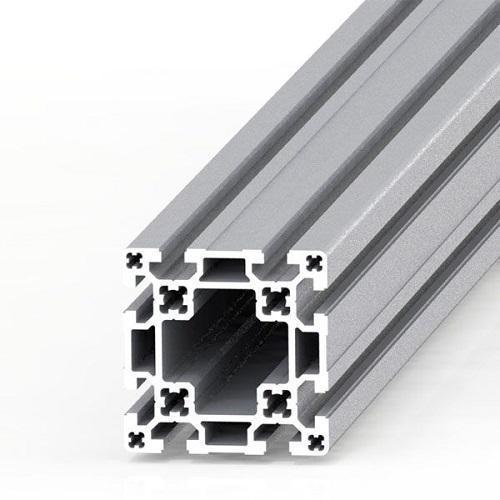

Industrial aluminum profiles are integral components in various sectors due to their strength, versatility, and durability. However, there’s a prevalent misconception that equates the quality of these profiles solely to their thickness. In this article, we aim to debunk this myth, shedding light on the true factors that determine the quality and suitability of industrial aluminum profiles.

Section 1: The Real Relationship Between Thickness and Quality

While it’s true that thicker industrial aluminum profiles offer enhanced load-bearing capacity, it’s crucial to understand that this is just one aspect of their overall quality. Quality encompasses a range of factors including material composition, manufacturing processes, and design. Blindly pursuing thickness can lead to unnecessary costs and suboptimal performance. It’s about finding the right balance and selecting profiles that meet the specific requirements of your application.

Section 2: Decoding the Thickness: Unit Weight and Price

The thickness of industrial aluminum profiles directly impacts their unit weight, influencing the overall cost. Thicker walls result in a higher weight per meter, driving up the price. For instance, within the same series of profiles, varying specifications necessitate different wall thicknesses. Recognizing these nuances is vital for making cost-effective and practical choices that align with your project’s budget and objectives.

Section 3: Thickness and Load-Bearing Capacity

The load-bearing capacity of industrial aluminum profiles is indeed affected by wall thickness. Thicker walls are typically used for large-scale frame structures that demand high stability and load-bearing capabilities. This ensures that the structures remain stable and secure, even under substantial loads. By providing real-world examples, we highlight the critical nature of selecting profiles with the appropriate thickness for high-bearing applications.

Section 4: Application Scope: Choosing the Right Profile

Industrial aluminum profiles come in a myriad of specifications, each designed for specific applications. From light profiles suited for small frames with minimal stress to heavy-duty profiles required for substantial structures, understanding the application scope is paramount. In this section, we guide you through the selection process, helping you choose the right profile based on your unique load-bearing and application requirements.

Conclusion

Selecting the appropriate industrial aluminum profile goes beyond just looking at thickness. It requires a holistic understanding of your project’s specific needs, the load-bearing requirements, and the application scope. By making informed choices, you ensure the longevity, stability, and effectiveness of your structures or products. Don’t let misconceptions guide your decisions; delve deeper and choose wisely.