Introduction

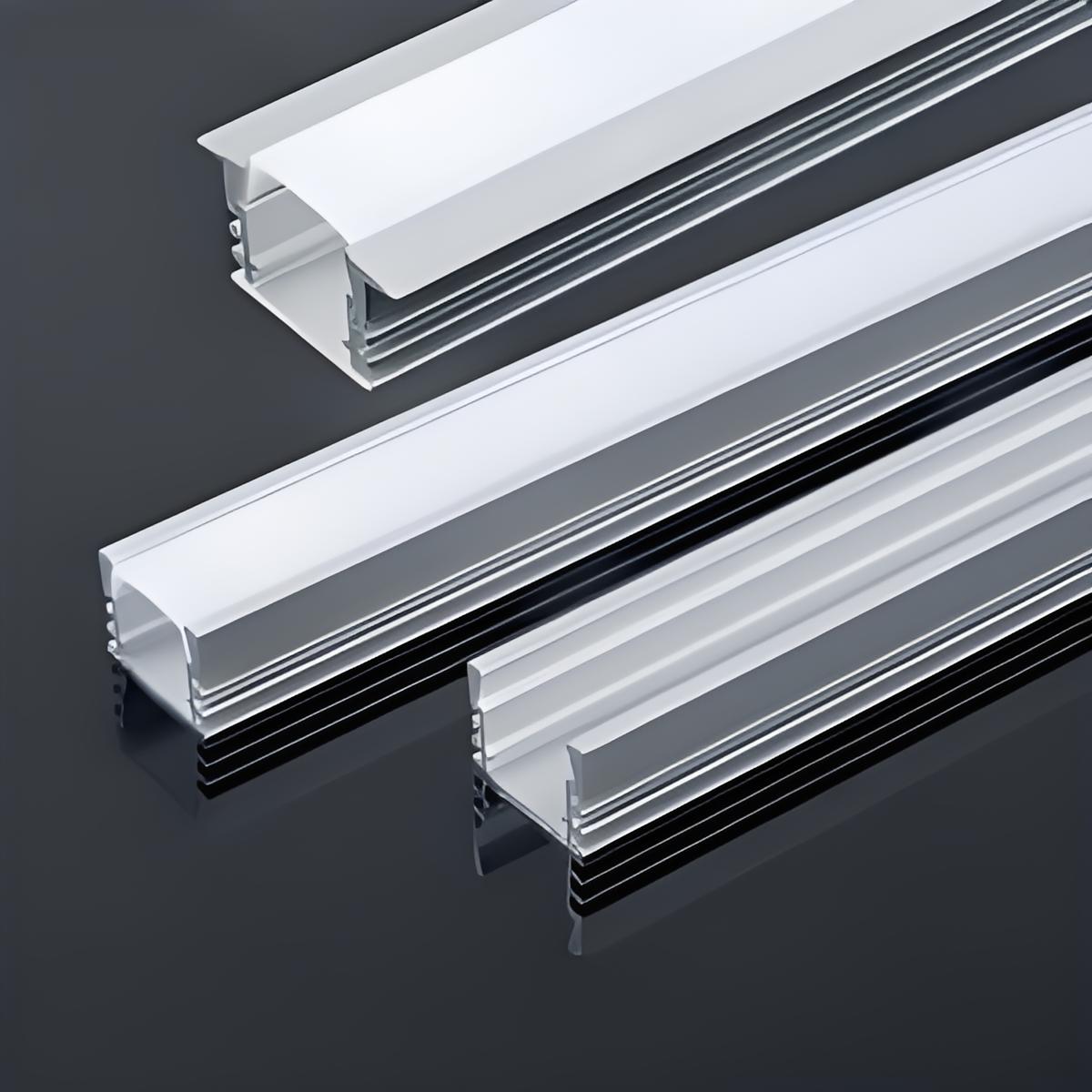

LED aluminum lamps play a crucial role in modern lighting applications, offering both efficient light gathering and static electricity release. Today, aluminum is the material of choice for constructing these lamps due to its numerous advantages over stainless steel. Let’s delve into the reasons behind this preference and explore the benefits it brings to LED lighting technology.

Heat Dissipation Properties of Aluminum

In the realm of LED lighting, effective heat dissipation is essential for maintaining optimal performance and longevity. Aluminum alloy surpasses steel in its ability to conduct heat, making it ideal for LED lamp shells and radiators. This superior heat dissipation capability ensures that LED lamps operate efficiently even under prolonged use, enhancing their reliability and lifespan.

Anti-Corrosion Properties of Aluminum

Another key advantage of aluminum is its natural resistance to corrosion, further enhanced through the anodizing process. The formation of a dense oxide film on the aluminum surface provides a protective barrier against environmental elements, prolonging the lifespan of LED lamps and ensuring consistent performance over time. This anti-corrosion feature is particularly beneficial in outdoor or harsh environment applications, where durability is paramount.

Conclusion

Aluminum emerges as the clear winner in LED lamp construction, offering unmatched heat dissipation and anti-corrosion properties. By leveraging the strengths of aluminum, LED lighting manufacturers can deliver products that not only excel in performance but also stand the test of time. Make the switch to aluminum and experience the difference in LED lighting solutions.