Introduction

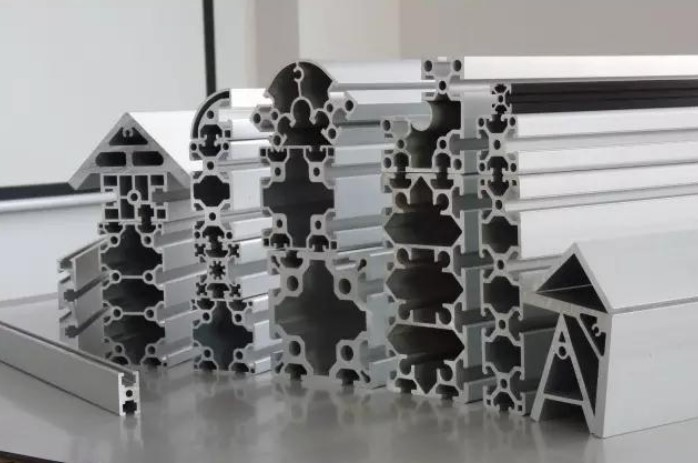

In the realm of industrial design and manufacturing, the selection of aluminum profiles is critical. Not just any material will suffice when durability, precision, and functionality are on the line. Industrial aluminum profiles, ubiquitous in both industrial settings and our daily lives, demand careful consideration. This guide demystifies the characteristics that distinguish superior quality aluminum profiles, ensuring that consumers and industry professionals alike make informed decisions.

The Significance of Raw Material Quality

The genesis of any industrial aluminum profile is the aluminum rod from which it is extruded. The quality of these rods is paramount, as it sets the stage for the profile’s overall performance. Superior rods, like the 6063-T5, boast a clean, spot-free surface with a hardness that resists deformation. When it comes to raw materials, cutting corners is not an option.

The Importance of Profile Thickness

The integrity of an aluminum profile hinges on its thickness. Different shapes come with varied rib or wall thicknesses, influencing both cost and performance. Thin profiles may be cheaper, but their reduced functionality can compromise a project’s success. By measuring and comparing, one can discern why some profiles are priced above others and ensure their selection can withstand the rigors of use.

The Critical Nature of Oxide Film Thickness

The oxide film is the unsung hero of an aluminum profile, warding off oxidation, simplifying cleaning, and resisting corrosion and static. Quality profiles feature an oxide film thickness of at least 8 μm. With professional tools available to measure this film, one can verify a manufacturer’s compliance and thereby the profile’s longevity and effectiveness.

Precision in Straightness for Optimal Functionality

Precision instruments require precision materials. Industrial aluminum profiles must exhibit exact straightness to function correctly in sensitive applications. A deviation of less than 0.8mm is often the standard for larger profiles, ensuring that the final product operates as intended.

How to Choose Quality Industrial Aluminum Profiles

Choosing the right aluminum profile is not merely a matter of chance. It involves understanding the interplay between quality materials, adequate thickness, oxide film standards, and precise straightness. Comparing samples from various manufacturers against these standards reveals the true value behind the price tags.

Conclusion

Understanding the key characteristics of industrial aluminum profiles is essential in selecting materials that offer the best balance of cost, durability, and performance. By emphasizing the importance of high-quality raw materials, sufficient thickness, appropriate oxide film coverage, and precise straightness, this guide equips you with the knowledge to select profiles that meet the highest industrial standards.

Call to Action

Invest in the longevity and efficacy of your industrial applications by choosing aluminum profiles that stand up to scrutiny. For further information or to discuss your specific needs, we invite you to reach out and engage with our team of experts.