Unlocking Customization: The Evolution of Aluminum for Modern Needs

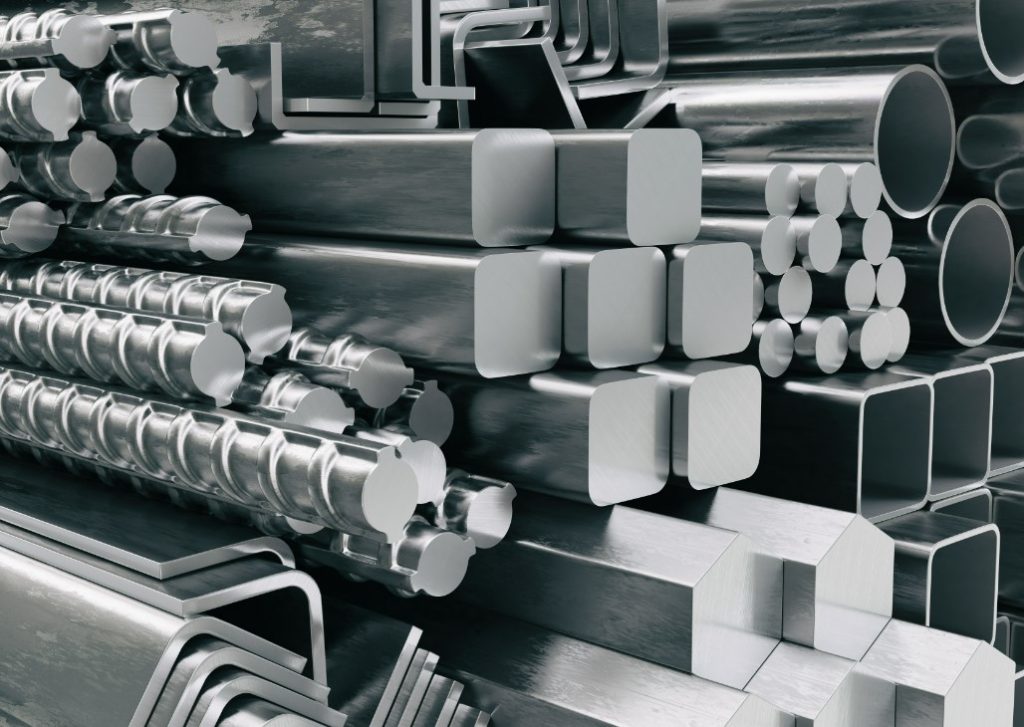

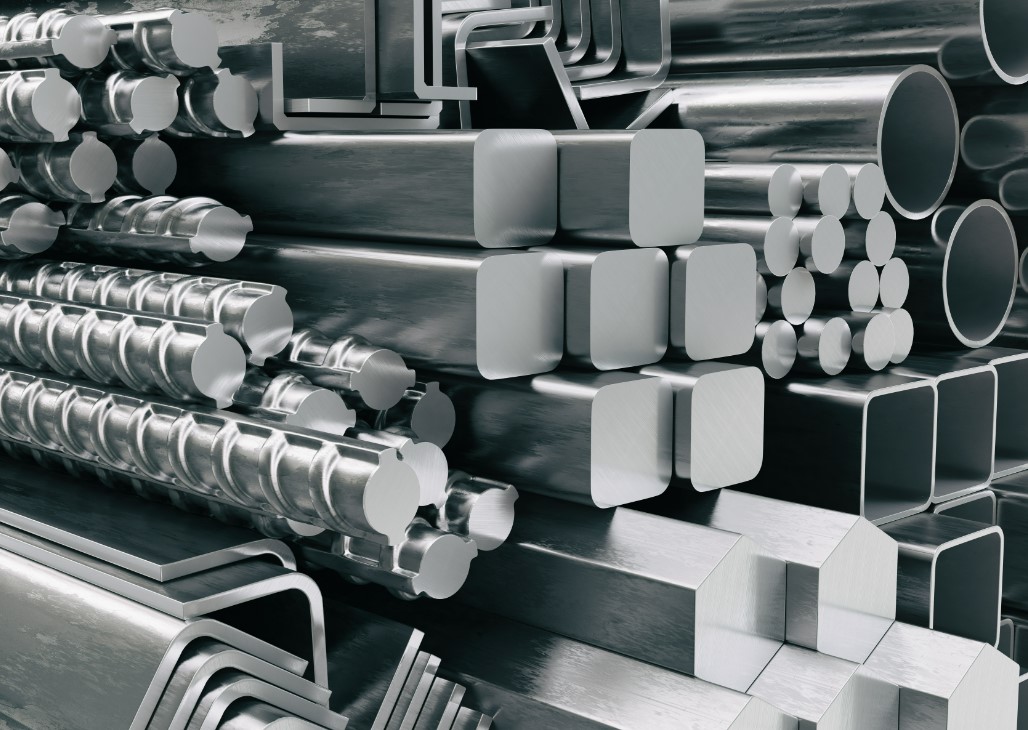

Aluminum, with its lightweight, strong, and corrosion-resistant properties, has long been a staple in industries ranging from construction to electronics. However, as technology advances and design preferences evolve, the one-size-fits-all approach to aluminum materials is becoming a thing of the past. Enter the age of customized aluminum manufacturing—a game-changer that’s reshaping how industries approach material use to fulfill unique project specifications.

The Rise of Customized Design in Manufacturing

Customized design is more than a trend; it’s a fundamental shift in the manufacturing landscape. By partnering with custom aluminum manufacturers, clients gain the ability to tailor the size, shape, and material properties of aluminum to their specific needs. This level of customization unlocks unparalleled design freedom and innovation potential, empowering engineers and designers to push the boundaries of what’s possible.

Dimensional Flexibility

Traditionally, aluminum came in standard sizes, limiting its application to a predefined range of uses. Today, customized aluminum manufacturers have shattered this limitation, offering aluminum in any size required by the customer. This flexibility is particularly impactful in the fields of architecture and electronics, where precision and adaptability can significantly influence the design and functionality of products.

Shape Versatility

Through processes like extrusion and stamping, custom aluminum manufacturers can produce materials in virtually any shape desired. This capability is revolutionizing the construction industry, where uniquely shaped aluminum components can serve both structural and decorative purposes, enhancing the aesthetic appeal of buildings and other structures.

Material Customization for Enhanced Properties

Custom aluminum doesn’t stop at size and shape. Manufacturers can also alter the material’s properties through alloying and oxidation, among other treatments, to meet specific performance requirements. Whether a project demands aluminum that withstands extreme stress or resists harsh environmental conditions, customized solutions are readily available.

Creativity and Innovation through Customization

The possibilities for innovation with custom aluminum are endless. In construction, for example, architects can design windows and doors with unique aluminum frames that not only add an artistic touch to buildings but also optimize space efficiency. These bespoke solutions demonstrate how customization is not just about meeting practical needs—it’s also about fulfilling the creative vision.

Applications Beyond Construction

The benefits of customized aluminum extend well beyond the construction sector. In transportation, lightweight yet strong aluminum materials are crucial for developing efficient, high-performance vehicles, from high-speed trains to aircraft. Meanwhile, in the rapidly evolving electronics industry, the demand for aluminum that is thinner, lighter, and offers better thermal conductivity is driving collaboration with custom manufacturers to keep pace with technological advancements.

Conclusion

The collaboration between industries and custom aluminum manufacturers is a testament to the versatility and adaptability of aluminum as a material. As we look to the future, the trend toward customization in aluminum manufacturing is poised to unlock even more possibilities for product innovation and design. Customized aluminum is not just shaping the present; it’s paving the way for a future where the only limit is our imagination.